Polylac® PA-746 High Flow Medium Impact ABS Resin

POLYLAC PA-746 is CHIMEI’s high-flow ABS resin. It has a melt flow index of 29 ml/10min and impact strength of 28 KJ/m2. This resin is ideal for thin-wall parts, offering easy molding of complex shapes. It maintains strength at low temperatures and resists heat well. With 39 MPa tensile strength and 60 MPa flexural strength, PA-746 is perfect for gadget cases and appliance components. Manufacturers value its processability and durability.

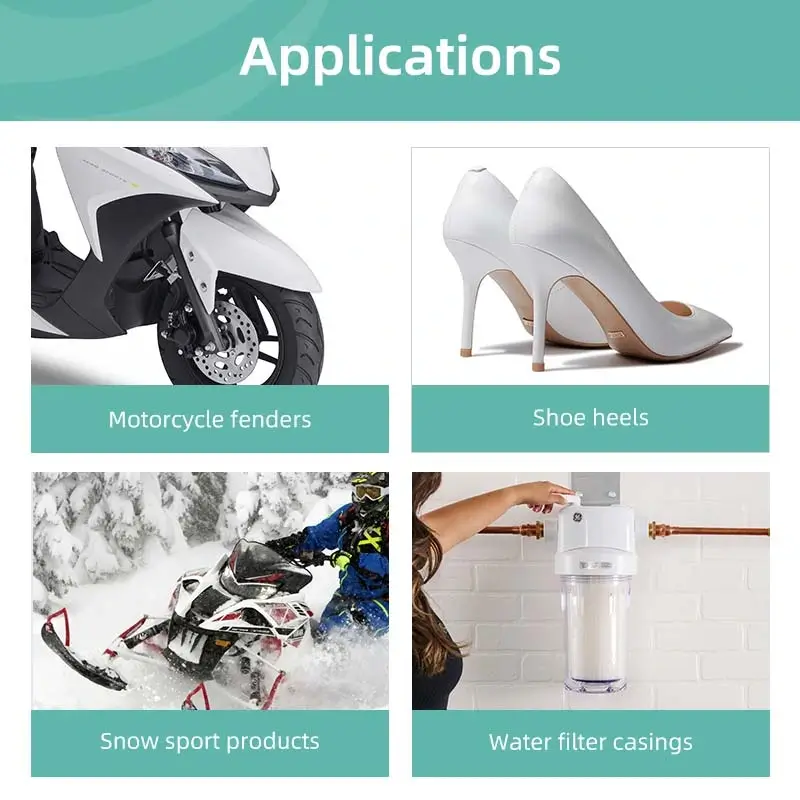

- Application: Suitable for thin wall and high impact strength molding parts

- Character: High flowability, high impact strength

Download

Access essential product documentation including technical data sheets, safety information, environmental certifications, and processing guides.

All documents are sourced directly from manufacturers and updated regularly for accuracy.

Polylac® PA-746 Datasheet

| High Flow ABS POLYLAC® PA-746 | ||||

| Product Description: High flow, Medium impact | ||||

| Properties | ISO Test Method | Test Condition | Unit | PA-746 |

| Melt Flow Index | 1133 | 220℃×10KG | ml/10 min | 29 |

| Mass Density | 1183 | 23 ℃ | g/cm3 | 1.03 |

| Tensile Strength | 527 | 50 mm/min, yield | MPa | 39 |

| 50 mm/min, break | MPa | 29 | ||

| Tensile Elongation | 527 | 50 mm/min | % | 35 |

| Flexural Strength | 178 | 2 mm/min | MPa | 60 |

| Flexural Modulus | 178 | 2 mm/min | GPa | 1.8 |

| Izod Impact Strength | 180/1A | 23℃, Notched | KJ/m2 | 28 |

| -30℃, Notched | KJ/m2 | 12 | ||

| Charpy Impact Strength | 179 | 23℃, Notched | KJ/m2 | 30 |

| -30℃, Notched | KJ/m2 | 14 | ||

| Vicat Softening Temp. | 306 | 50℃/hr;1KG | ℃ | 103 |

| 50℃/hr;5KG | ℃ | 94 | ||

| Heat Distortion Temp. | 75/A | 1.8MPa, unannealed | ℃ | 82 |

| 1.8MPa, annealed | ℃ | 96 | ||

| Coefficient of Linear Thermal Expansion | 11359 | – | – | 9.2 x 10-5 |

| Flammability | – | UL-94 | – | 1.5mm HB |

| Mold Shrinkage | 294-4 | – | % | 0.4~0.7 |

| Symbol | 1043 | – | – | >ABS< |

| March 11, 2024 | ||||

Polylac® PA-746 UL Product iQ

| POLYLAC® PA-746 UL Product iQ | ||

| File Number: E56070 | Yellow Card™ | Acrylonitrile Butadiene Styrene (ABS) “POLYLAC”, furnished as pellets |

| FLAMMABILITY PROPERTIES | VALUE | TEST METHOD |

| Flammability | ANSI/UL 94 | |

| 1.5 mm, Color: ALL | HB | |

| 3.0 mm, Color: ALL | HB | |

| ISO/IEC FLAMMABILITY PROPERTIES | VALUE | TEST METHOD |

| Flammability | IEC 60695-11-10 | |

| 1.5 mm, Color: ALL | HB75 | |

| 3.0 mm, Color: ALL | HB40 | |

| ELECTRICAL PROPERTIES | VALUE | TEST METHOD |

| Hot-wire Ignition (HWI) | UL 746A | |

| 1.5 mm | PLC 4 | |

| 3.0 mm | PLC 3 | |

| High Amp Arc Ignition (HAI) | UL 746A | |

| 1.5 mm | PLC 0 | |

| 3.0 mm | PLC 0 | |

| Comparative Tracking Index (CTI) | PLC 0 | UL 746A |

| High Voltage Arc Tracking Rate (HVTR) | PLC 2 | |

| Volume Resistivity | 1.0E+16 ohms·cm | ASTM D257/IEC |

| 60093 | ||

| High Voltage, Low Current Arc Resistance | PLC 6 | |

| THERMAL PROPERTIES | VALUE | TEST METHOD |

| Relative Thermal Index – Electrical Strength | UL 746B | |

| 1.5 mm | 85 °C | |

| 3.0 mm | 85 °C | |

| Relative Thermal Index – Mechanical Impact | UL 746B | |

| 1.5 mm | 80 °C | |

| 3.0 mm | 80 °C | |

| Relative Thermal Index – Mechanical Strength | UL 746B | |

| 1.5 mm | 85 °C | |

| 3.0 mm | 85 °C | |

| Report Date: 1983-06-23 | ||

Related Polylac® ABS Plastics

No post found!

Advanced Manufacturing