ACRYREX® CM-205 PMMA Transparent Grade Extrusion

Chimei ACRYREX CM-205 PMMA resin combines heat resistance, high strength, and exceptional extrusion performance. Ideal for precision-molded components like automotive lights, lenses, and appliance parts, this high-viscosity material ensures durability and clarity even in demanding environments.

Basic Features:

- Manufacturer: CHIMEI

- Packaging: 25kg bag

- Character: Heat resistant / High strength / Extrusion

Key technical data (ISO)

- Heat Resistance: Vicat Softening Temp = 115°C | Heat Distortion Temp = 95–104°C

- Strength: Tensile Strength = 70 MPa | Flexural Strength = 103 MPa

- Processing: Melt Flow Index = 1.9 ml/10min | Mold Shrinkage = 0.2–0.6%

- Safety: UL-94 HB flammability rating (1.5mm thickness)

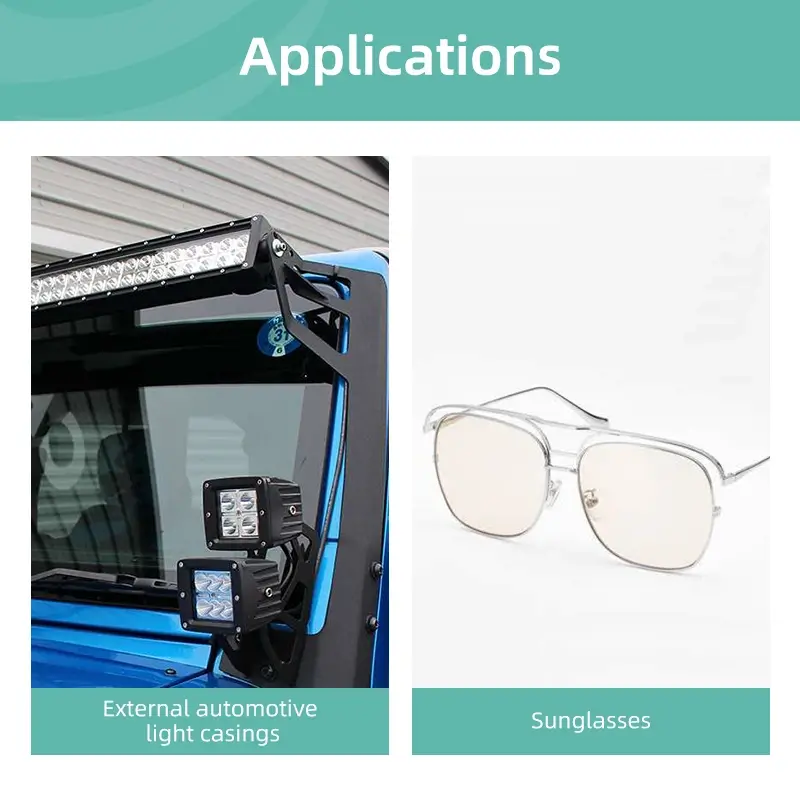

Applications

- Car Lights: Heat-resistant lenses and housings for headlights or interior lighting.

- Optical Lenses: High-clarity panels for displays, signage, or industrial optics.

- Home Appliances: Durable components like dishwasher windows or refrigerator panels.

Acryrex® CM-205 Datasheet

| General PMMA ACRYREX® CM-205 Product Description: High viscosity | ||||

| Properties | ISO Test Method | Test Condition | Unit | CM-205 |

| Melt Flow Index | 1133 | 230℃×3.8KG | ml/10 min | 1.9 |

| Mass Density | 1183 | 23 ℃ | g/cm3 | 1.19 |

| Tensile Strength | 527 | 5 mm/min, yield | MPa | 70 |

| 50 mm/min, break | MPa | 70 | ||

| Tensile Elongation | 527 | 50 mm/min | % | 12 |

| Flexural Strength | 178 | 2 mm/min | MPa | 103 |

| Flexural Modulus | 2 mm/min | GPa | 2.8 | |

| Izod Impact Strength | 180/1A | 23℃, Notched | KJ/m2 | 2 |

| -30℃, Notched | KJ/m2 | – | ||

| Charpy Impact Strength | 179 | 23℃, Notched | KJ/m2 | 2 |

| Charpy ‘-30℃, Notched | KJ/m2 | – | ||

| Vicat Softening Temp. | 306 | 50℃/hr;1KG | ℃ | 115 |

| 50℃/hr;5KG | ℃ | 107 | ||

| Heat Distortion Temp. | 75/A | 1.8MPa, unannealed | ℃ | 95 |

| 1.8MPa, annealed | ℃ | 104 | ||

| Coefficient of Linear Thermal Expansion | 11359 | – | – | 6 X 10-5 |

| Flammability | – | UL-94 | – | 1.5mm HB |

| Mold Shrinkage | 294-4 | – | % | 0.2~0.6 |

| Symbol | 1043 | – | – | >PMMA< |

| August 23, 2023 Notes:These are typical properties only and are not to be construed as specifications. Users should confirm results by their own test | ||||

Related Acryrex® PMMA Plastics

Advanced Manufacturing