ACRYREX® CM-211 PMMA Transparent Grade High Flow

Chimei ACRYREX CM-211 PMMA resin is a high-flow, low-viscosity material designed for precision molding. Ideal for intricate parts in home appliances and daily necessities, it combines superior processability with durability, heat resistance, and compliance with safety standards like UL 94 HB.

- Manufacturer: CHIMEI

- Packaging: 25kg bag

- Character: High flow/Processability

Key technical data (ISO)

- Flow Efficiency: 16 ml/10 min (ISO 1133)

- Mechanical Strength: 65 MPa tensile, 95 MPa flexural

- Heat Tolerance: 103°C Vicat

- Safety Compliance: UL 94 HB flammability rating

- Low Shrinkage: 0.2–0.6%

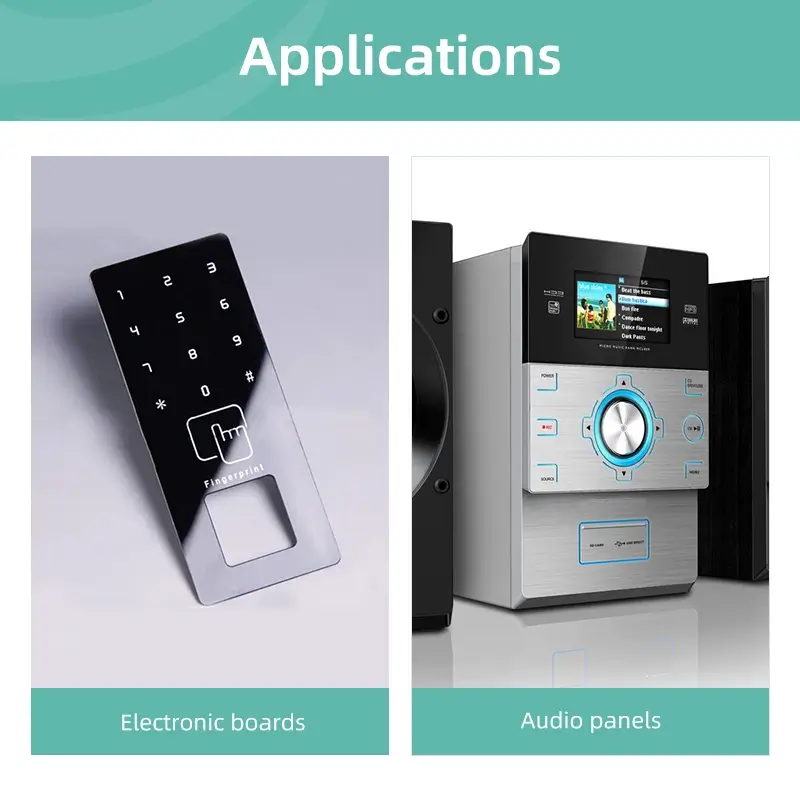

Applications

- Home Appliance Parts: Transparent microwave turntables, blender jars, and refrigerator compartments.

- Daily Necessities: Shatter-resistant cosmetic containers, bathroom accessories, and kitchenware.

- Electronics: Light diffusers, control panels, and touch-sensitive covers requiring clarity and toughness.

Acryrex® CM-211 Datasheet

| General PMMA ACRYREX® CM-211 Product Description: Low viscosity | ||||

| Properties | ISO Test Method | Test Condition | Unit | CM-211 |

| Melt Flow Index | 1133 | 230℃×3.8KG | ml/10 min | 16 |

| Mass Density | 1183 | 23 ℃ | g/cm3 | 1.19 |

| Tensile Strength | 527 | 5 mm/min, yield | MPa | 65 |

| 50 mm/min, break | MPa | 65 | ||

| Tensile Elongation | 527 | 50 mm/min | % | 6 |

| Flexural Strength | 178 | 2 mm/min | MPa | 95 |

| Flexural Modulus | 2 mm/min | GPa | 2.7 | |

| Izod Impact Strength | 180/1A | 23℃, Notched | KJ/m2 | 2 |

| -30℃, Notched | KJ/m2 | – | ||

| Charpy Impact Strength | 179 | 23℃, Notched | KJ/m2 | 2 |

| Charpy ‘-30℃, Notched | KJ/m2 | – | ||

| Vicat Softening Temp. | 306 | 50℃/hr;1KG | ℃ | 103 |

| 50℃/hr;5KG | ℃ | 96 | ||

| Heat Distortion Temp. | 75/A | 1.8MPa, unannealed | ℃ | 78 |

| 1.8MPa, annealed | ℃ | 98 | ||

| Coefficient of Linear Thermal Expansion | 11359 | – | – | 6 X 10-5 |

| Flammability | – | UL-94 | – | 1.5mm HB |

| Mold Shrinkage | 294-4 | – | % | 0.2~0.6 |

| Symbol | 1043 | – | – | >PMMA< |

| August 23, 2023 Notes:These are typical properties only and are not to be construed as specifications. Users should confirm results by their own test | ||||

Acryrex® CM-211 UL Product iQ

| ACRYREX® CM-211 | UL Product iQ | ||

| File Number: E56070 | Yellow Card™ | Polymethyl Methacrylate (PMMA) “ACRYREX”, furnished as pellets |

| (v) – Vicat softening temperature of 95 degree C achieved at 3.0mm | ||

| FLAMMABILITY PROPERTIES | VALUE | TEST METHOD |

| Flammability | ANSI/UL 94 | |

| 1.5 mm, Color: ALL | HB | |

| 3.0 mm, Color: ALL | HB | |

| ISO/IEC FLAMMABILITY PROPERTIES | VALUE | TEST METHOD |

| Flammability | IEC 60695-11-10 | |

| 1.5 mm, Color: ALL | HB75 | |

| 3.0 mm, Color: ALL | HB40 | |

| ELECTRICAL PROPERTIES | VALUE | TEST METHOD |

| Hot-wire Ignition (HWI) | UL 746A | |

| 1.5 mm | PLC 4 | |

| 3.0 mm | PLC 3 | |

| High Amp Arc Ignition (HAI) | PLC 0 | UL 746A |

| (1.5 mm) | ||

| Comparative Tracking Index (CTI) | PLC 1 | UL 746A |

| High Voltage Arc Tracking Rate (HVTR) | PLC 0 | |

| High Voltage, Low Current Arc Resistance | PLC 6 | |

| THERMAL PROPERTIES | VALUE | TEST METHOD |

| Relative Thermal Index – Electrical Strength | UL 746B | |

| 1.5 mm | 50 °C | |

| 3.0 mm | 50 °C | |

| Relative Thermal Index – Mechanical Impact | UL 746B | |

| 1.5 mm | 50 °C | |

| 3.0 mm | 50 °C | |

| Relative Thermal Index – Mechanical Strength | UL 746B | |

| 1.5 mm | 50 °C | |

| 3.0 mm | 50 °C | |

| Report Date: 1982-06-22 | ||

Related Acryrex® PMMA Plastics

Advanced Manufacturing