Polylac® PA-737 High Flow Grade Medium Impact ABS Resin

Chi Mei Polylac PA-737 is a high-flow ABS resin engineered for large-area or thin-walled injection-molded products. Combining medium impact resistance with exceptional flow properties, it simplifies complex molding processes while maintaining durability, making it ideal for automotive, electronics, and appliance manufacturing.

- Manufacturer: Chimei

- Character: Transparent UV Resistant Grade

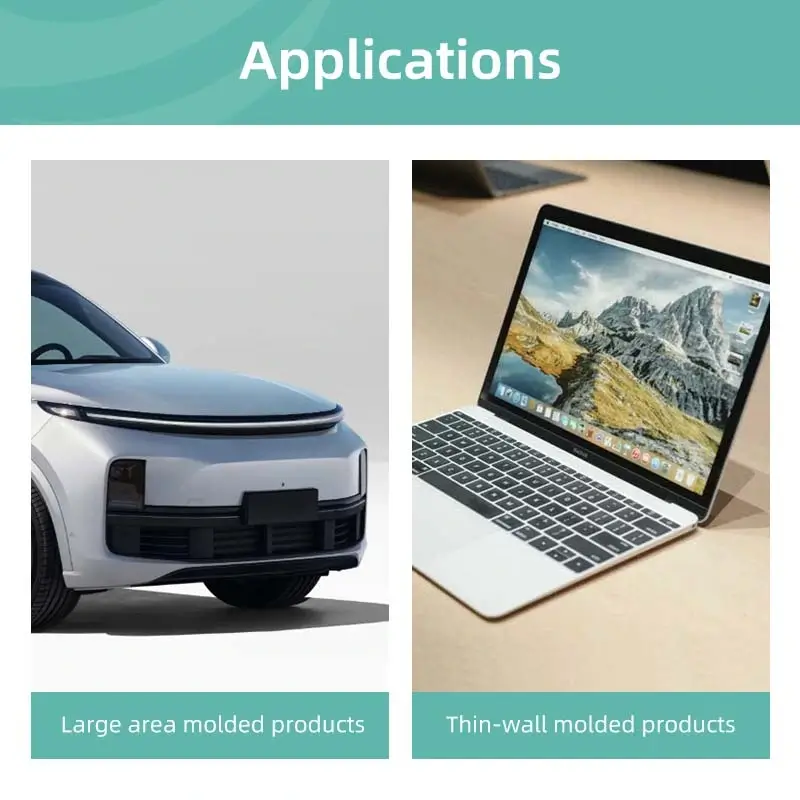

- Application: Large area or thin-wall molded products

Key technical data (ISO)

- Flow Performance: 31 ml/10 min (ISO 1133, 220°C/10KG)

- Impact Strength: 24 KJ/m² (23°C, notched Izod) | 10 KJ/m² (-30°C)

- Thermal Resistance: Vicat 103°C (1KG) | HDT 96°C (1.8MPa, annealed)

- Safety Compliance: UL94 HB flammability rating (1.5mm/3.0mm)

- Electrical Safety: CTI PLC 1 for low tracking risk in electrical components

Application

- Automotive: Trim panels, ventilation ducts, and dashboard components.

- Consumer Electronics: Ultra-thin laptop frames, smartphone casings, and TV bezels.

- Appliances: Vacuum cleaner housings, refrigerator liners, and washing machine panels.

Chimei Polylac® PA-737 Datasheet

| High Flow ABS POLYLAC® PA-737 | ||||

| Product Description: High flow, Medium impact | ||||

| Properties | ISO Test Method | Test Condition | Unit | PA-737 |

| Melt Flow Index | 1133 | 220℃×10KG | ml/10 min | 31 |

| Mass Density | 1183 | 23 ℃ | g/cm3 | 1.04 |

| Tensile Strength | 527 | 50 mm/min, yield | MPa | 38 |

| 50 mm/min, break | MPa | 32 | ||

| Tensile Elongation | 527 | 50 mm/min | % | 15 |

| Flexural Strength | 178 | 2 mm/min | MPa | 60 |

| Flexural Modulus | 2 mm/min | GPa | 1.9 | |

| Izod Impact Strength | 180/1A | 23℃, Notched | KJ/m2 | 24 |

| -30℃, Notched | KJ/m2 | 10 | ||

| Charpy Impact Strength | 179 | 23℃, Notched | KJ/m2 | 25 |

| -30℃, Notched | KJ/m2 | 11 | ||

| Vicat Softening Temp. | 306 | 50℃/hr;1KG | ℃ | 103 |

| 50℃/hr;5KG | ℃ | 96 | ||

| Heat Distortion Temp. | 75/A | 1.8MPa, unannealed | ℃ | 81 |

| 1.8MPa, annealed | ℃ | 96 | ||

| Coefficient of Linear | 11359 | – | – | 9.0 x 10-5 |

| Thermal Expansion | – | UL-94 | – | 1.5mm HB |

| Flammability | 294-4 | – | % | 0.4~0.7 |

| Mold Shrinkage | 1043 | – | – | >ABS< |

| Symbol | January 21, 2025 | |||

Related Polylac® ABS Plastics

No post found!

Advanced Manufacturing