Suke TPE 75N13 scratch resistance

Suke TPE 75N13 is a high-performance thermoplastic elastomer engineered for durability, offering a comfortable surface, scratch resistance, and exceptional size stability. Ideal for 3C electronics, kitchenware, and tool components, it combines flexibility with industrial-grade strength for demanding applications.

- Manufacturer: Suke Plastics

- Character: comfortable surface, scratch resistance, size stability

Key technical data (ISO)

- Hardness:75±3 Shore A

- Tensile Strength: 51.6 MPa

- Elongation at Break: 558%

- Tear Strength: 34.3 Kn/m

- Melt Flow Rate: 4.43 g/10min

- Processing Temp Range: 180–190°C

- Pre-Drying: 80°C for 3 hours

Download

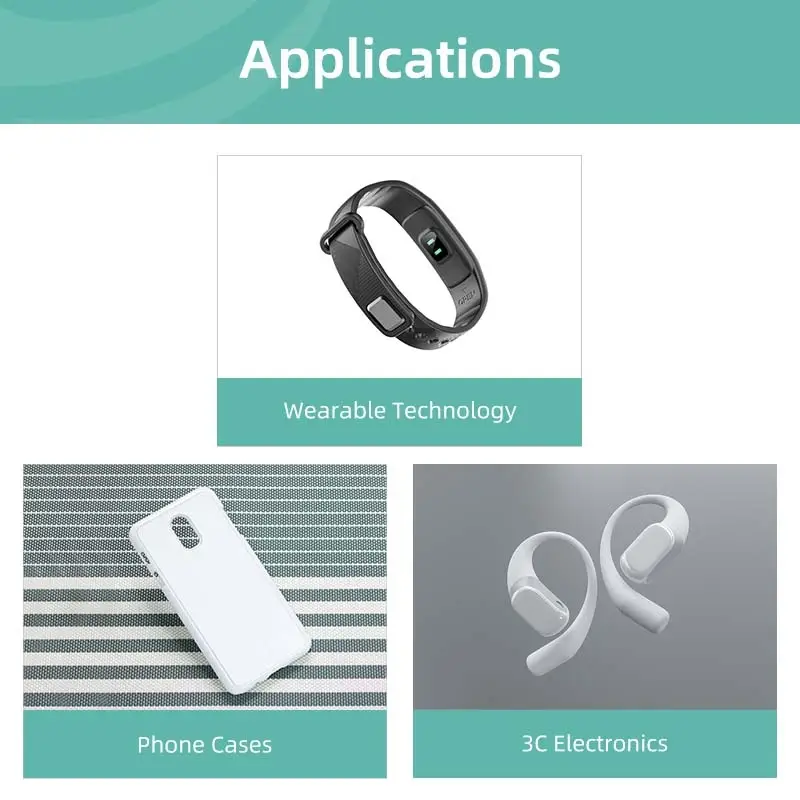

Application

- IT & Communications: Server connectors, 5G router housings.

- Electrical Appliances: Circuit breakers, switchgear components.

- Household Appliances: Durable coffee machine gears, vacuum cleaner structural parts.

- Industrial Electrical: Motor housings, relay insulators.

Suke TPE 75N13 Datasheet

| Suke TPE 75N13 Data Sheet | |||

| Product Description: comfortable surface, scratch resistance, size stability | |||

| Physical Properties | Test Standard | Units | Typical Value |

| Pecific grav | ASTM D792 | g/cm³ | 1.112 |

| Hardness | ASTM D2240 | shoreA | 75±3 |

| Tensile strength | ASTM D412 | MPa | 51.6 |

| Elongation at break | ASTM D412 | % | 558 |

| Tearing streng | ASTM D624 | Kn/m | 34.3 |

| Melt indexgravity | ASTM D1238 | g/10min | 4.43 |

| Processing conditions | Range | ||

| Pre-drying Conditions | 80℃,3 Hr | ||

| Nozzle temp | 190℃ | ||

| Screw 1 temp | 185℃ | ||

| Screw 2 temp | 185℃ | ||

| Screw 3 temp | 180℃ | ||

Related Suke TPE Resin Plastics

Advanced Manufacturing