WONDERLOY® PC-992 Flame Retardant Grade Weather Resistance

WONDERLOY PC-992 is a flame-retardant PC/ASA resin engineered for demanding environments. Combining UV stability (UL 746C f1), high flow for complex molds, and non-halogenated flame retardancy (1.5mm V-0), it’s ideal for outdoor and automotive applications where durability and safety are non-negotiable.

- Character: Weather resistance, High flow, Non-brominated and non-chlorinated flame retardant, 1.5mm V-0

Key technical data

- Flow Efficiency: 30 ml/10 min (260°C, 5kg)

- Strength & Flexibility: Tensile Strength 60 MPa | Impact Resistance 56 KJ/m² (23°C)

- Heat Resistance: Heat Distortion Temp. 93°C (1.8MPa)

- Flame Retardancy: UL 94 V-0 (1.5mm) | Non-halogenated

- Certifications: UL 746C f1 (outdoor use) | UL iQ Listing (File E56070)

- Molding Stability: Low shrinkage (0.4–0.6%)

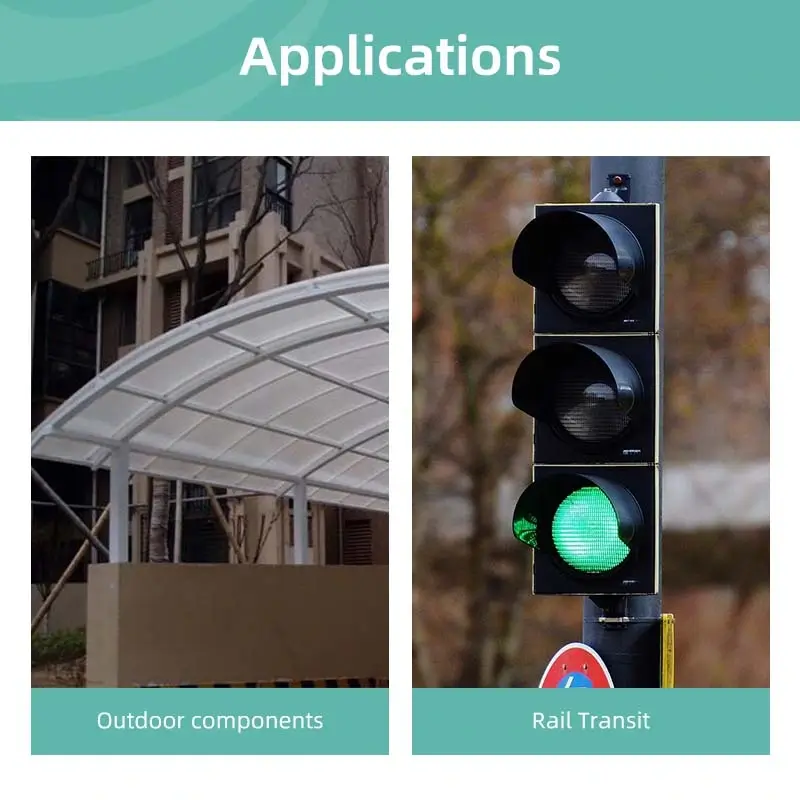

Applications

- Outdoor Electrical Enclosures: UV-stable housings for solar inverters or telecom equipment.

- Automotive Exterior Parts: Mirror housings, grilles, and trims resistant to fading and impact.

- Industrial Connectors: Flame-retardant components compliant with safety regulations.

- Consumer Electronics: Durable, high-flow casings for outdoor smart devices.

Wonderloy® PC-992 Datasheet

| Flame Retardant PC Alloy WONDERLOY® PC-992 Product Description: PC/ASA, 1.5mm V-0, UL 746C f1, UV Stabilized, High Flow | ||||

| Properties | ISO Test Method | Test Condition | Unit | PC-992 |

| Melt Flow Index | 1133 | 260℃×2.16KG | ml/10 min | 10 |

| 260℃×5KG | 30 | |||

| Spiral flow | CHIMEI | 260℃,2mm,V:50%,P:50% | cm | 24.3 |

| Mass Density | 1183 | 23 ℃ | g/cm3 | 1.20 |

| Tensile Strength | 527 | 50 mm/min, yield | MPa | 60 |

| 50 mm/min, break | 52 | |||

| Tensile Elongation | 527 | 50 mm/min | % | 100 |

| Flexural Strength | 178 | 2 mm/min | MPa | 90 |

| Flexural Modulus | 2 mm/min | GPa | 2.4 | |

| Izod Impact Strength | 180/1A | 23℃, Notched | KJ/m2 | 56 |

| -30℃, Notched | 8 | |||

| Charpy Impact Strength | 179 | 23℃, Notched | KJ/m2 | 56 |

| -30℃, Notched | 8 | |||

| Vicat Softening Temp. | 306 | 50℃/hr;1KG | ℃ | 118 |

| 50℃/hr;5KG | 110 | |||

| Heat Distortion Temp. | 75/A | 1.8MPa, unannealed | ℃ | 93 |

| Dielectric Constant | IEC 60250 | 1MHz | — | 3.1 |

| Volume Resistivity | IEC 60093 | — | Ohm X m | 3.9E+15 |

| Surface Resistivity | IEC 60093 | — | Ohm | 2.9E+15 |

| Coefficient of Linear Thermal Expansion | 11359 | – | – | 8*10-⁵ |

| Flammability | – | UL-94 | – | 1.5mm V-0 |

| Weatherability | – | UL 746C | – | f1 |

| Mold Shrinkage | 294-4 | – | % | 0.4~0.6 |

| Symbol | 1043 | – | – | >PC+ASA- FR(40)< |

| June 29, 2023 Notes:These are typical properties only and are not to be construed as specifications. Users should confirm results by their own test. | ||||

Wonderloy® PC-992 UL Product iQ

| WONDERLOY PC-992(f1) | UL Product iQ | ||

| File Number: E56070 | Yellow Card™ | Polycarbonate/Acrylonitrile Styrene Acrylate (PC/ASA) “WONDERLOY”, furnished as pellets |

| (f1) – Suitable for outdoor use with respect to exposure to Ultraviolet Light, Water Exposure and Immersion in accordance with UL 746C. | ||

| FLAMMABILITY PROPERTIES | VALUE | TEST METHOD |

| Flammability | V-0 | ANSI/UL 94 |

| (1.5 to 1.7 mm, Color: NC, WT, RD) | ||

| ISO/IEC FLAMMABILITY PROPERTIES | VALUE | TEST METHOD |

| Flammability | V-0 | IEC 60695-11-10 |

| (1.5 to 1.7 mm, Color: NC, WT, RD) | ||

| THERMAL PROPERTIES | VALUE | TEST METHOD |

| Relative Thermal Index – Electrical Strength | 50 °C | UL 746B |

| (1.5 to 1.7 mm) | ||

| Relative Thermal Index – Mechanical Impact | 50 °C | UL 746B |

| (1.5 to 1.7 mm) | ||

| Relative Thermal Index – Mechanical Strength | 50 °C | UL 746B |

| (1.5 to 1.7 mm) | ||

| PHYSICAL PROPERTIES | VALUE | TEST METHOD |

| UV Exposure & Water Immersion | f1 | UL 746C |

Related Wonderloy® pC/ASA Plastics

Advanced Manufacturing