WONDERLOY® PC-345 high-flow Material

WONDERLOY® PC-345 is a high-flow PC/ABS resin ideal for complex or thin-walled parts. It offers excellent moldability, high impact strength, and good heat resistance. With a UL94 HB rating at 1.5mm, it’s suitable for various applications. This versatile material combines easy processing with durability, making it a go-to choice for manufacturers seeking quality and efficiency.

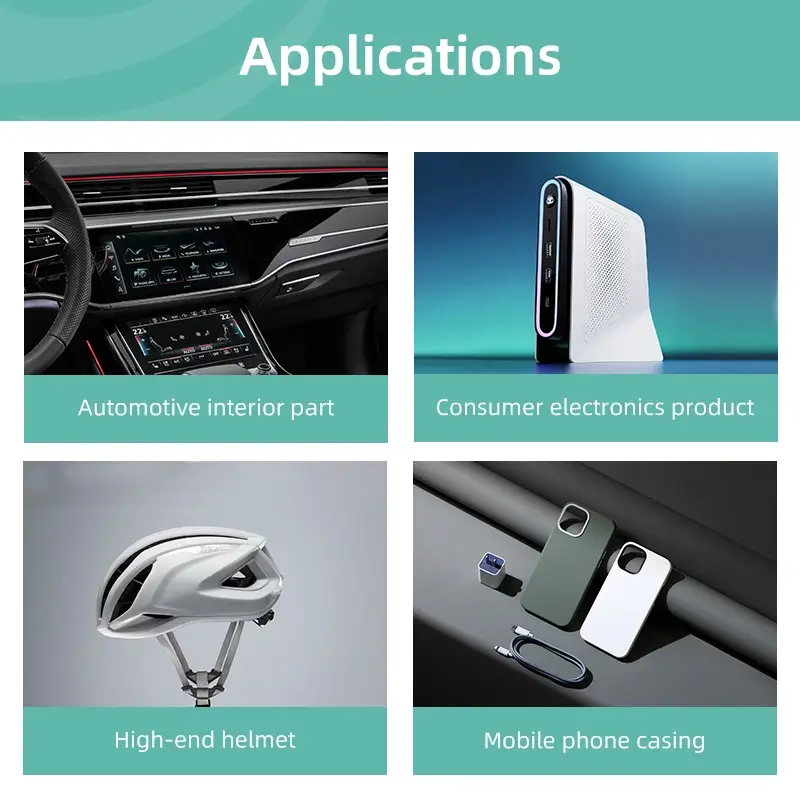

- Application: Automotive interior part/Consumer electronics product/High-end helmet/Mobile phone casing/General molding product

- Character: High flow grade, 1.5mm HB

Download

Access essential product documentation including technical data sheets, safety information, environmental certifications, and processing guides. All documents are sourced directly from manufacturers and updated regularly for accuracy.

WONDERLOY® PC-345 Datasheet

| General WONDERLOY® PC-345 | ||||

| Product Description: High flow | ||||

| Properties | ISO Test Method | Test Condition | Unit | PC-345 |

| Melt Flow Index | 1133 | 260℃×5KG | ml/10 min | 19 |

| Spiral flow | CHIMEI | 260℃,2mm, | cm | 43 |

| V:50%,P:50% | ||||

| Mass Density | 1183 | 23 ℃ | g/cm3 | 1.1 |

| Tensile Strength | 527 | 50 mm/min, yield | MPa | 50 |

| 50 mm/min, break | MPa | 42 | ||

| Tensile Elongation | 527 | 50 mm/min | % | 105 |

| Flexural Strength | 178 | 2 mm/min | MPa | 75 |

| Flexural Modulus | 178 | 2 mm/min | GPa | 2.1 |

| Izod Impact Strength | 180/1A | 23℃, Notched | KJ/m2 | 60 |

| -30℃, Notched | KJ/m2 | 15 | ||

| Charpy Impact Strength | 179 | 23℃, Notched | KJ/m2 | 60 |

| -30℃, Notched | KJ/m2 | 15 | ||

| Vicat Softening Temp. | 306 | 50℃/hr;1KG | ℃ | 150 |

| 50℃/hr;5KG | ℃ | 145 | ||

| Heat Distortion Temp. | 75/A | 1.8MPa, unannealed | ℃ | 125 |

| 1.8MPa, annealed | ℃ | 140 | ||

| Dielectric Constant | IEC 60250 | 1MHz | — | 3.1 |

| Volume Resistivity | IEC 60093 | — | Ohm X m | 1E+16 |

| Surface Resistivity | IEC 60093 | — | Ohm | 1E+16 |

| Coefficient of Linear Thermal Expansion | 11359 | – | – | 8.5*10⁻⁵ |

| Flammability | – | UL-94 | – | 1.5mm HB |

| Mold Shrinkage | 294-4 | – | % | 0.4~0.6 |

| Symbol | 1043 | – | – | >PC+ABS< |

| January 12, 2024 | ||||

WONDERLOY® PC-345 UL Product iQ

| WONDERLOY® PC-345 | UL Product iQ | ||

| File Number: E56070 | Yellow Card™ | Polycarbonate/Acrylonitrile Butadiene Styrene (PC/ABS) “WONDERLOY”, furnished as pellets |

| FLAMMABILITY PROPERTIES | VALUE | TEST METHOD |

| Flammability | ANSI/UL 94 | |

| 1.5 mm, Color: ALL | HB | |

| 3.0 mm, Color: ALL | HB | |

| ISO/IEC FLAMMABILITY PROPERTIES | VALUE | TEST METHOD |

| Flammability | IEC 60695-11-10 | |

| 1.5 mm, Color: ALL | HB75 | |

| 3.0 mm, Color: ALL | HB40 | |

| ELECTRICAL PROPERTIES | VALUE | TEST METHOD |

| Hot-wire Ignition (HWI) | UL 746A | |

| 1.5 mm | PLC 4 | |

| 3.0 mm | PLC 3 | |

| High Amp Arc Ignition (HAI) | UL 746A | |

| 1.5 mm | PLC 0 | |

| 3.0 mm | PLC 0 | |

| Comparative Tracking Index (CTI) | PLC 2 | UL 746A |

| Dielectric Strength | 32 kV/mm | ASTM D149 |

| High Voltage Arc Tracking Rate (HVTR) | PLC 2 | |

| Volume Resistivity | 1.0E+14 ohms·cm | ASTM D257/IEC 60093 |

| High Voltage, Low Current Arc Resistance | PLC 6 | |

| THERMAL PROPERTIES | VALUE | TEST METHOD |

| Relative Thermal Index – Electrical Strength | UL 746B | |

| 1.5 mm | 60 °C | |

| 3.0 mm | 60 °C | |

| Relative Thermal Index – Mechanical Impact | UL 746B | |

| 1.5 mm | 60 °C | |

| 3.0 mm | 60 °C | |

| Relative Thermal Index – Mechanical Strength | UL 746B | |

| 1.5 mm | 60 °C | |

| 3.0 mm | 60 °C | |

| PHYSICAL PROPERTIES | VALUE | TEST METHOD |

| Dimensional Change | 0.0 % | ASTM D1042/ISO 2796 |

| Report Date: 2001-01-12 | ||

Related WONDERLOY® PC Alloy Plastics

Advanced Manufacturing