Polylac® PA-757H High Flow Grade Medium Strength ABS

POLYLAC PA-757H by Chimei is a high-flow, high-impact ABS resin engineered for demanding applications. Combining exceptional moldability (30 ml/10 min MFI) with robust impact resistance (25 KJ/m²) and a glossy finish, it’s ideal for household appliances, motorcycle parts, and thin-walled components. Trusted for performance and reliability.

- Manufacturer: Chimei

- Character: High flowability, medium strength

Key technical data (ISO)

- Melt Flow Index: 30 ml/10 min (220°C, 10kg)

- Impact Strength: 25 KJ/m² (23°C) / 12 KJ/m² (-30°C)

- Heat Resistance: Vicat Softening Temp 105°C; HDT 83°C (1.8MPa)

- Flammability: UL94 HB (1.5mm)

- Mold Shrinkage: 0.4–0.7%

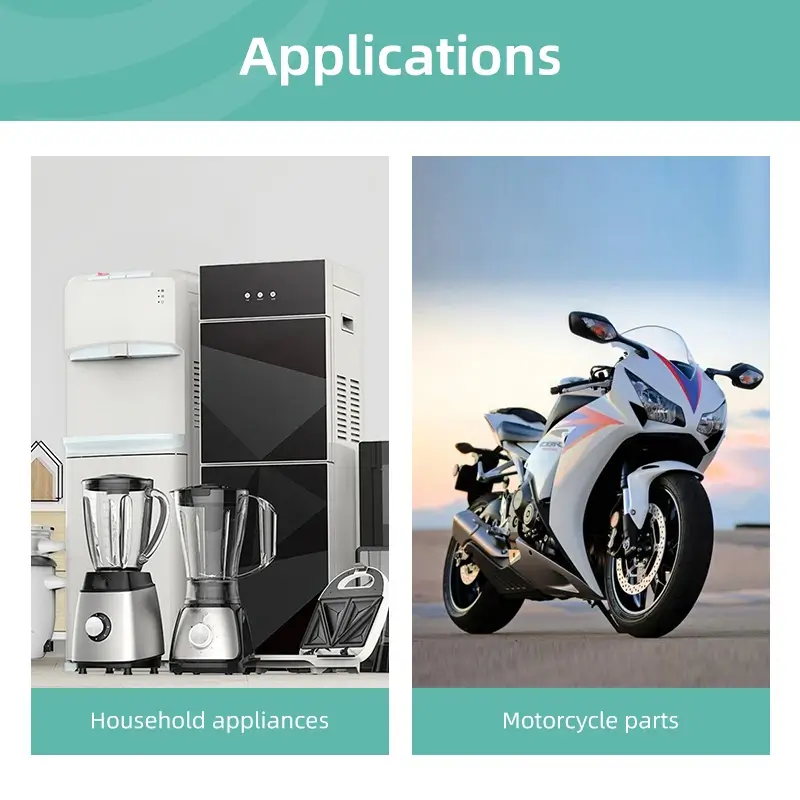

Application

- Household Appliances: in thin-walled blender jars or coffee maker housings.

- Motorcycle Parts: from glossy helmet shells to durable side panels.

- Large/Thin-Wall Components: TV bezels or laptop casings.

Chimei Polylac® PA-757H Datasheet

| General ABS POLYLAC® PA-757H | ||||

| Product Description: Better balance in high flow and high impact, High gloss | ||||

| Properties | ISO Test Method | Test Condition | Unit | PA-757H |

| Melt Flow Index | 1133 | 220℃×10KG | ml/10 min | 30 |

| Mass Density | 1183 | 23 ℃ | g/cm3 | 1.04 |

| Tensile Strength | 527 | 50 mm/min, yield | MPa | 39 |

| 50 mm/min, break | MPa | 31 | ||

| Tensile Elongation | 527 | 50 mm/min | % | 45 |

| Flexural Strength | 178 | 2 mm/min | MPa | 61 |

| Flexural Modulus | 2 mm/min | GPa | 2 | |

| Izod Impact Strength | 180/1A | 23℃, Notched | KJ/m2 | 25 |

| -30℃, Notched | KJ/m2 | 12 | ||

| Charpy Impact Strength | 179 | 23℃, Notched | KJ/m2 | 26 |

| -30℃, Notched | KJ/m2 | 13 | ||

| Vicat Softening Temp. | 306 | 50℃/hr;1KG | ℃ | 105 |

| 50℃/hr;5KG | ℃ | 97 | ||

| Heat Distortion Temp. | 75/A | 1.8MPa, unannealed | ℃ | 83 |

| 1.8MPa, annealed | ℃ | 98 | ||

| Coefficient of Linear | 11359 | – | – | 8.6 x 10-5 |

| Thermal Expansion | – | |||

| Flammability | 294-4 | UL-94 | – | 1.5mm HB |

| Mold Shrinkage | 1043 | – | % | 0.4~0.7 |

| Symbol | – | – | >ABS< | |

Related Polylac® ABS Plastics

No post found!

Advanced Manufacturing