TAIRILOY® AC3100 Self Extinguishing Grade

TAIRILOY AC3100 PC/ABS Resin by FCFC is a halogen-free, flame-retardant alloy combining high flow and toughness. It offers UL compliance, V-0 flame resistance, and heat resistance. Features R110 hardness, 2350 MPa flexural modulus, and passes ball pressure tests. Engineered for durable, lightweight designs.

- Manufacturer: FCFC (Formosa Chemicals & Fibre Corporation)

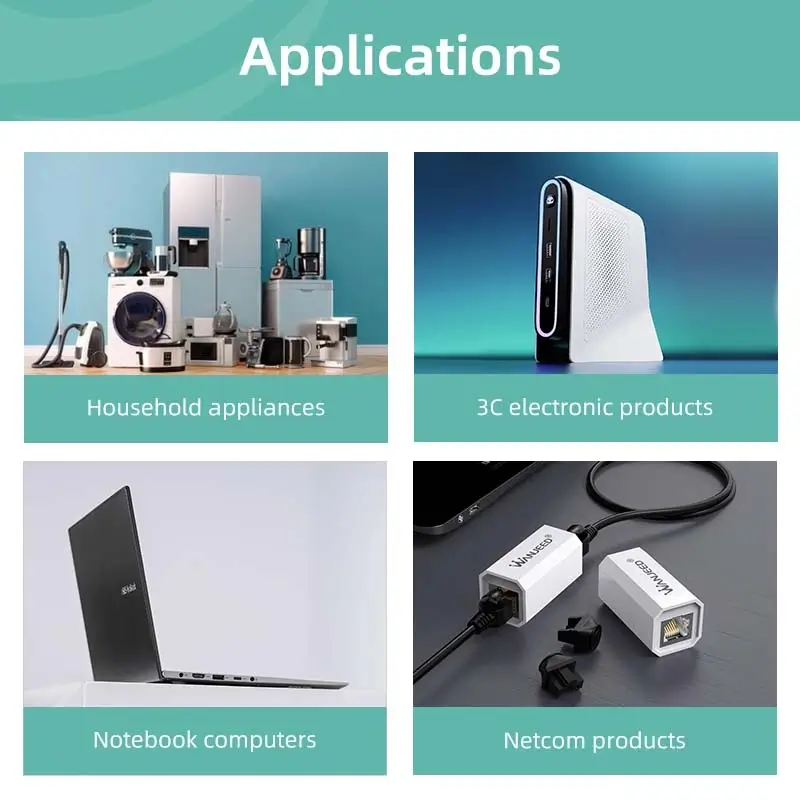

- Application: Household appliances, 3C electronic products, notebook computers, Netcom products, computer peripheral products

- Character: Flame retardant, Halogen free

Key technical data (ISO)

- Melt Flow Index: 21 g/10 min (260°C) – Excellent flow for complex molds.

- Thermal Resistance: Vicat softening point @ 117°C – Retains shape under heat.

- Flame Rating: V-0 (1.0–3.0mm), 5VA/5VB (2.3mm+) – Meets global safety standards.

- Electrical Safety: PLC 0 for HAI/CTI – Minimizes arc risks in power components.

- RTI (Electrical/Strength): Up to 90°C – Long-term reliability in heated environments.

Applications

- Household Appliances: Flame-retardant housings for coffee makers, hairdryers.

- 3C Electronics: Smartphone cases, tablet frames, and charger plugs.

- Notebook Computers: Lightweight yet impact-resistant laptop bodies.

- Netcom Products: Router enclosures, modem casings.

- Computer Peripherals: Keyboards, printer components, and thin-wall connectors.

Tairiloy® AC3100 Datasheet

| General Purpose Grade FCFC TAIRILOY® AC3100 Data Sheet | ||||

| Product Description: Metal plating | ||||

| Property | Unit | Test Method | Test Condition | Model AC3100 |

| Melt Flow Index | g/10 min | ISO 1133 | 260℃ × 5kg | 21 |

| IZOD Impact Strength | J/m | ISO 180 | 23 ℃ 3.2mm | 540 |

| Charpy Impact Strength | kJ/m² | ISO 179 | 23 ℃ 4mm | 40 |

| Specific Gravity | – | ISO 1183 | 23℃/23℃ | 1.08 |

| Flexural Strength | Mpa | ISO 178 | 23 ℃ | 86 |

| Flexural Modulus | Mpa | ISO 178 | 23 ℃ | 2350 |

| Rockwell Hardness | R-scale | ISO 2039-2 | 23℃ | R-110 |

| Vicat Softening Point | ℃ | ISO 306 | VICAT(10N ℃) | 117 |

| Molding Shrinkage | % | ISO 2577 | 3.2mm | 0.4 ~ 0.6 |

| Combustibility | UL-94 | File No. E162823 | HB 1.5 ~ 1.65 mm | |

| All tests were run under laboratory conditions, ASTM, ISO testing procedures. | ||||

| The data are intended as a general guide only. | ||||

| Formosa Chemicals & Fibre Corp. Plastics Div. | ||||

Tairiloy® AC3100 UL Product iQ

| TAIRILOY® AC310(+) UL Product iQ | ||

| File Number: E162823 | Polycarbonate/Acrylonitrile Butadiene Styrene (PC/ABS), pellets | |

| (+) – Replace by one digital 0-9 or one alphabet A-Z, unconcerned with formula or constituent changed | ||

| Flammability | Value | Test Method |

| Flame Rating | UL 94 | |

| 0.8 mm, ALL | V-2 | IEC 60695-11-10, -20 |

| 1.0 mm, ALL | V-0 | |

| 1.2 mm, ALL | V-0 | |

| 1.5 mm, ALL | V-0 | |

| 2.3 mm, ALL | V-0, 5VB | |

| 3.0 mm, ALL | V-0, 5VA | |

| Electrical | Value | Test Method |

| Hot-wire Ignition (HWI) | UL 746 | |

| 0.8 mm | PLC 3 | |

| 1.0 mm | PLC 3 | |

| 1.2 mm | PLC 3 | |

| 1.5 mm | PLC 3 | |

| 2.3 mm | PLC 2 | |

| High Amp Arc Ignition (HAI) | UL 746 | |

| 0.8 mm | PLC 0 | |

| 1.0 mm | PLC 0 | |

| 1.2 mm | PLC 0 | |

| 1.5 mm | PLC 0 | |

| 2.3 mm | PLC 0 | |

| Comparative Tracking Index (CTI) | PLC 0 | UL 746 |

| High Voltage Arc Tracking Rate (HVTR) | PLC 3 | UL 746 |

| Arc Resistance | PLC 7 | ASTM D495 |

| Thermal | Value | Test Method |

| RTI Elec | UL 746 | |

| 0.8 mm | 60.0°C | |

| 1.0 mm | 60.0°C | |

| 1.2 mm | 60.0°C | |

| 1.5 mm | 90.0°C | |

| 2.3 mm | 90.0°C | |

| 3.0 mm | 90.0°C | |

| RTI Imp | UL 746 | |

| 0.8 mm | 60.0°C | |

| 1.0 mm | 60.0°C | |

| 1.2 mm | 60.0°C | |

| 1.5 mm | 85.0°C | |

| 2.3 mm | 85.0°C | |

| 3.0 mm | 85.0°C | |

| Thermal | Value | Test Method |

| RTI Str | UL 746 | |

| 0.8 mm | 60.0°C | |

| 1.0 mm | 60.0°C | |

| 1.2 mm | 60.0°C | |

| 1.5 mm | 90.0°C | |

| 2.3 mm | 90.0°C | |

| 3.0 mm | 90.0°C | |

| Ball Pressure Test (75°C, 3.00 mm) | Pass | IEC 60695-10-2 |

Advanced Manufacturing