TAIRIREX GP535N GPPS Resin General Grade

TAIRIREX GP535N is a general-purpose polystyrene (GPPS) resin that shines with its heat resistance. It’s great for crafting kitchenware like microwave-safe containers, sturdy lamp covers, decorative sheets, and toys. This plastic offers clarity, stiffness, and cost-efficiency, making it a go-to for manufacturers needing tough, heat-safe plastic solutions.

- Manufacturer: FCFC (Formosa Chemicals & Fibre Corporation)

- Character: Heat resistance

Key technical data (ISO)

- Melt Flow Index: 4.5 g/10min

- Tensile Strength: 44 MPa

- Flexural Strength: 76 MPa

- Heat Deflection Temp (HDT): 95°C (1.8 MPa)

- Vicat Softening Point: 100°C

- Flammability Rating: HB (UL 94)

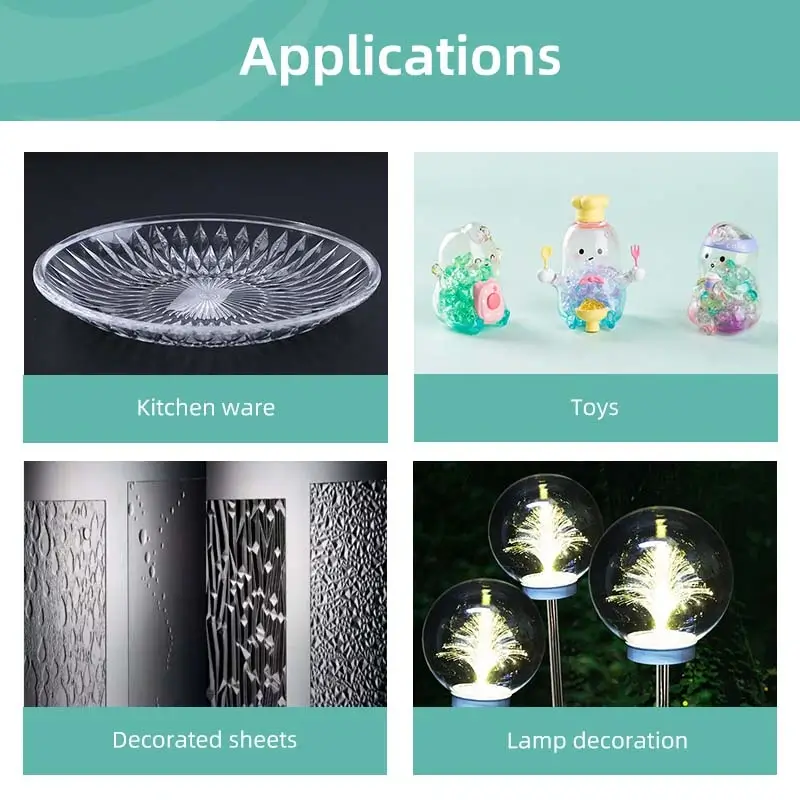

Application

- Kitchenware: Microwave-safe containers (heat resistance ensures no warping).

- Lamp Covers: Maintains clarity and stability near bulbs (HDT 95°C).

- Decorated Sheets: Vibrant finishes with crack-resistant durability (Charpy 10.8 kJ/m²).

- Toys: Safe, impact-resistant designs meeting global safety standards (HB flammability).

Tairirex® GP535N Datasheet

| General purpose grade FCFC TAIRIREX® GP535N Data Sheet | ||||

| Product Description: Heat resistance | ||||

| Property | Unit | Test Method | Test Condition | Model GP535N |

| Melt Flow Index | g/10min | ISO 1133 | 200℃ × 5kg 49N | 4.5 |

| IZOD Impact Strength | kJ/m² | ISO 180 | 23℃, 4mm, Unnotched | 1.6 |

| Charpy Impact Strength | kJ/m² | ISO 179 | 23℃, 4mm GPPS has no notch, HIPS has a notch | 10.8 |

| Tensile Strength | Mpa | ISO 527 | 23℃, 20mm/min | 44 |

| Tensile Modulus | Mpa | ISO 527 | 23℃, 1mm/min | 3300 |

| Tensile Elongation | % | ISO 527 | 23℃, 20mm/min | 3 |

| Flexural Strength | Mpa | ISO 178 | 23℃, 2mm/min | 76 |

| Flexural Modulus | Mpa | ISO 178 | 23℃, 2mm/min | 3100 |

| Vicat Softening Point | ℃ | ISO 306 | Annealed 80℃*2hr, 4mm,10N 50℃/h | 100 |

| Reidual Monomer | ppm max | – | 700 | |

| Heat Deflection Temperature | ℃ | ISO 75/A | Annealed 80℃*2hr,120℃/h,1.8Mpa 4mm | 95 |

| Combustibility | UL-94 | File No. E162823 | HB 1.5 ~ 1.7 mm | |

Tairirex® GP535N UL Product iQ

| TAIRIREX® GP535# UL Product iQ | ||

| File Number: E162823 | Polystyrene (PS), pellets | |

| # – May be followed by the suffix with letter A or N or number 0 (zero). | ||

| Flammability | Value | Test Method |

| Flame Rating | ||

| 1.5 to 1.7 mm, ALL | HB | UL 94 |

| 1.5 to 1.7 mm, ALL | HB75 | IEC 60695-11-10, -20 |

| Electrical | Value | Test Method |

| Hot-wire Ignition (HWI) (1.5 to 1.7 mm) | PLC 3 | UL 746 |

| High Amp Arc Ignition (HAI) (1.5 to 1.7 mm) | PLC 0 | UL 746 |

| Comparative Tracking Index (CTI) | PLC 1 | UL 746 |

| High Voltage Arc Tracking Rate (HVTR) | PLC 2 | UL 746 |

| Arc Resistance | PLC 5 | ASTM D495 |

| Thermal | Value | Test Method |

| RTI Elec | UL 746 | |

| 1.5 to 1.7 mm | 50.0°C | |

| 3.0 mm | 50.0°C | |

| RTI Imp | UL 746 | |

| 1.5 to 1.7 mm | 50.0°C | |

| 3.0 mm | 50.0°C | |

| RTI Str | UL 746 | |

| 1.5 to 1.7 mm | 50.0°C | |

| 3.0 mm | 50.0°C | |

Advanced Manufacturing