Suke 1065 PC/ABS Resin General Purpose Grade

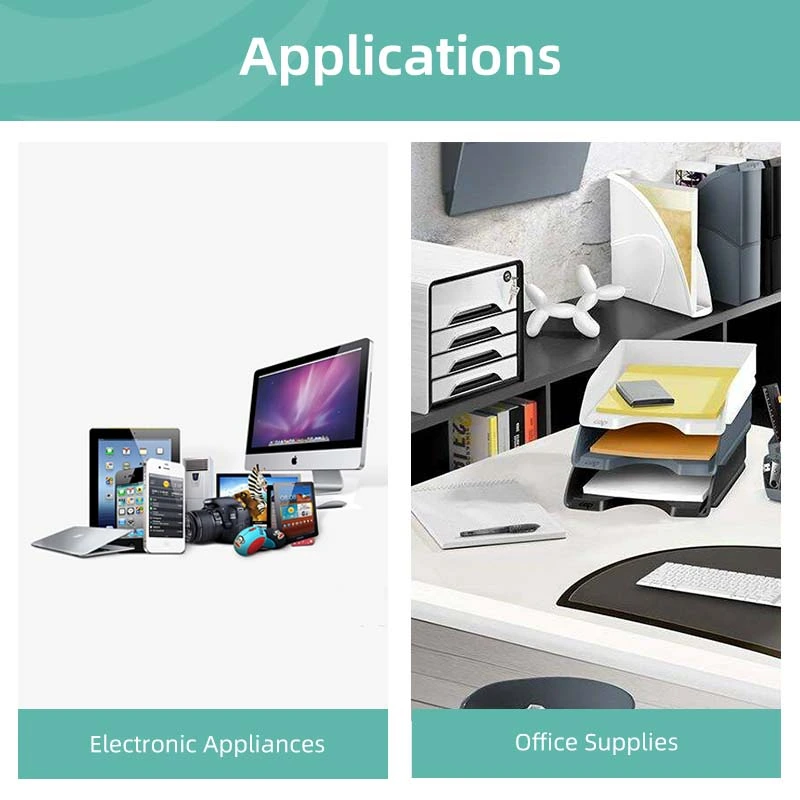

Suke 1065 is a high-performance, general-purpose PC/ABS resin offering exceptional balance. Its good comprehensive performance combines the strength of Polycarbonate (PC) with the processability of Acrylonitrile Butadiene Styrene (ABS), making it ideal for demanding applications across electronics and office equipment. Experience reliability and ease of manufacturing.

- Manufacturer: Suke Plastics

- Character: Good comprehensive performance

- Application: Electrical &electronic, Office supplies

Key technical data (ASTM)

- Density: 1.14 g/cm³

- Mold Shrinkage: 0.4-0.7%

- Tensile Strength: 57 MPa

- Flexural Strength: 75 MPa

- Flexural Modulus: 2200 MPa

- Impact Strength (IZOD Notched, 23°C): 55 KJ/m²

- Elongation at Break: 50%

- Heat Deflection Temp (HDT @ 1.8 MPa): 103°C

- Melt Temperature: 260°C

- Pre-Drying: 90°C-100°C for 3 hours

- Mold Temperature: 80°C

- Max Processing Temp: 280°C

Download

Application

- Electrical & Electronic (E&E): Computer monitor bezels and housings; Printer and copier exteriors and internal components; Power tool housings; Consumer electronics enclosures; Electrical connectors and sockets.

- Office Supplies: Durable casings for staplers, hole punches, tape dispensers; Frames and bodies for desktop organizers; Components for projectors and presentation equipment; Robust housings for calculators and electronic office devices.

Features & Benefits

Related Suke PC/ABS Products

Advanced Manufacturing