Suke D555 PC/ABS Resin General Purpose Grade

Suke D555 PC/ABS Resin is a high-performance, general-purpose grade engineered for exceptional all-around properties. Combining polycarbonate’s toughness with ABS’s processability, it delivers reliability for demanding industrial applications—ideal for cost-effective, durable components.

- Manufacturer: Suke Plastics

- Character: Good comprehensive performance

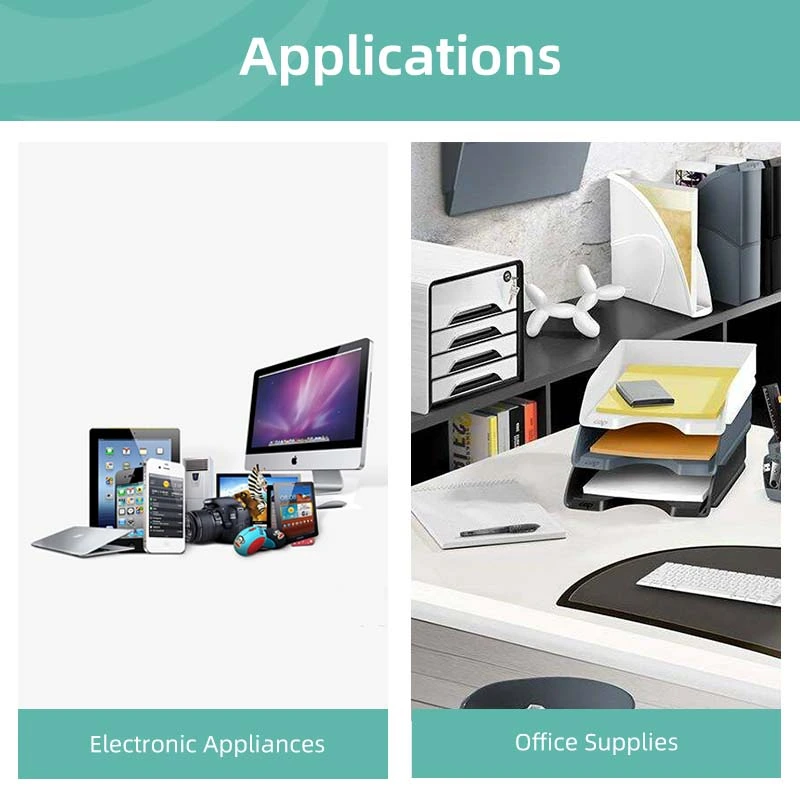

- Application: Electrical &electronic, Office supplies

Key technical data (ASTM)

- Density: 1.10 g/cm³

- Mold Shrinkage: 0.4–0.7% (2mm)

- Melt Flow Rate: 21 g/10min (260°C, 5kg)

- Tensile Strength: 48 MPa

- Flexural Strength: 72 MPa

- Impact Strength (Notched IZOD): 50 KJ/m²

- Heat Deflection Temp: 92°C (1.8MPa)

- Processing Drying: 85–95°C for 3 hours

- Processing Melt Temp: 250°C (Max 270°C)

- Processing Mold Temp: 80°C

Download

Application

- Electrical & Electronic: Power tool housings, connectors, circuit breakers.

- Office Supplies: Printer frames, keyboard components, ergonomic device casings.

Features & Benefits

Related Suke PC/ABS Products

Advanced Manufacturing