Suke D570 PC/ABS Resin General Purpose Grade

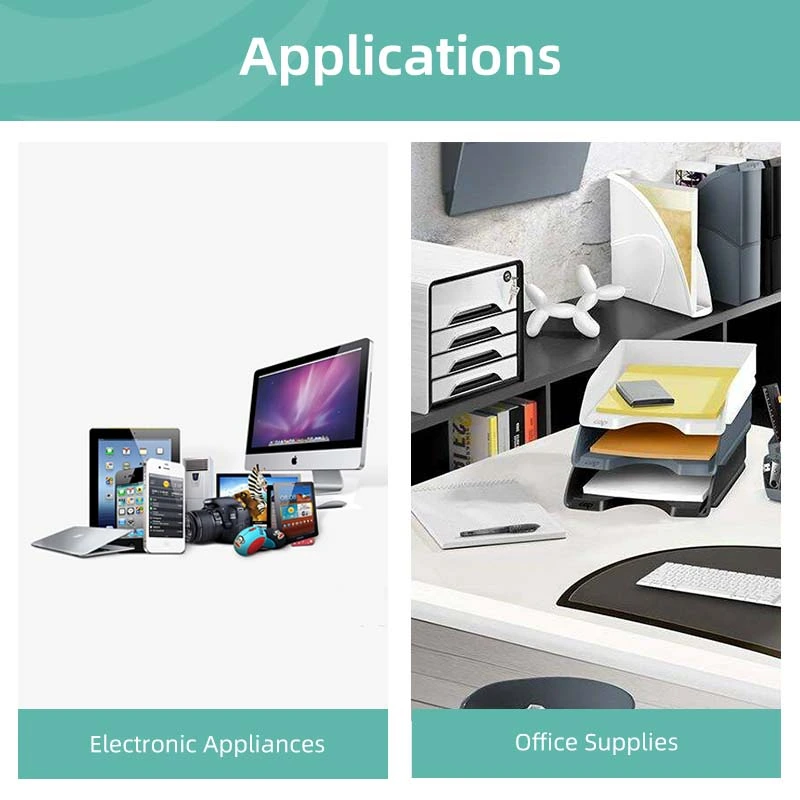

Suke D570 PC/ABS Resin delivers exceptional all-around performance for demanding industrial applications. This versatile engineering thermoplastic combines polycarbonate’s strength with ABS’s processability, offering balanced mechanical properties, ease of molding, and reliability for electronics, tools, and office equipment.

- Manufacturer: Suke Plastics

- Character: Good comprehensive performance

- Application: Electrical &electronic, Office supplies

Key technical data (ASTM)

- Density: 1.07 g/cm³

- Mold Shrinkage: 0.4–0.7% (2mm)

- Tensile Strength: 47 MPa

- Flexural Strength: 70 MPa

- Impact Strength (Notched IZOD): 42 KJ/m²

- HDT @1.8MPa: 86°C

- Drying: 80–85°C for 3 hrs

- Melt Temp: 240°C

- Injection Pressure: 60–100 MPa

- Mold Temp: 80°C

Download

Application

- Electrical & Electronics: Power tool housings, router casings, connector components.

- Office Supplies: Printer/scanner panels, keyboard frames, durable desk accessories.

Features & Benefits

Related Suke PC/ABS resin Products

Advanced Manufacturing