Suke 1030 PC/ABS Resin General Purpose Grade

Suke 1030 is a versatile PC/ABS resin offering good comprehensive performance for industrial applications. This general-purpose grade combines strength, ease of processing, and thermal stability—ideal for demanding electrical, electronic, and office equipment components.

- Manufacturer: Suke Plastics

- Character: Good comprehensive performance

- Application: Electrical &electronic, Office supplies

Key technical data (ASTM)

- Density: 1.07 g/cm³

- Mold Shrinkage: 0.4–0.7%

- Impact Strength: 45 KJ/m²

- Flammability: UL94-test

- Flexural Strength: 65 MPa

- Melt Temp: 240°C

- Mold Temperature: 80°C

Download

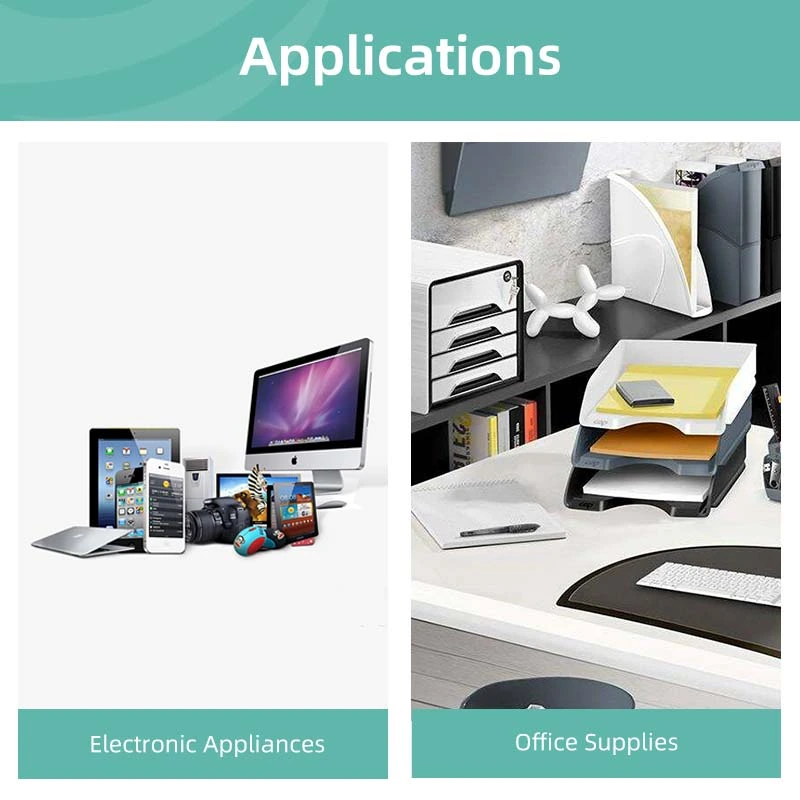

Application

- Electrical & Electronics: Laptop/phone housings; Power tool grips; Connectors and sockets.

- Office Supplies: Printer/scanner components; Durable chair bases; Keyboard frames.

Features & Benefits

Related Suke PC/ABS Products

Advanced Manufacturing