Suke D535 PC/ABS Resin General Purpose Grade

Suke D535 is a premium PC/ABS resin engineered for good comprehensive performance as a general purpose grade. This versatile material strikes the ideal balance between impact strength, heat resistance, rigidity, and ease of processing, making it a trusted workhorse for demanding industrial applications. Perfect for engineers needing a dependable, all-rounder thermoplastic.

- Manufacturer: Suke Plastics

- Character: Good comprehensive performance

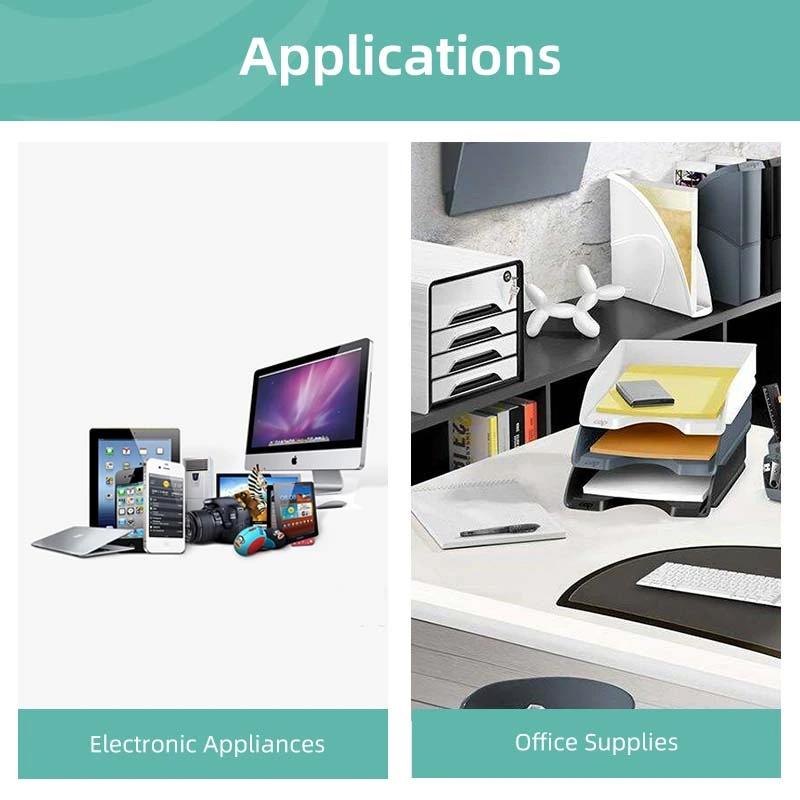

- Application: Electrical &electronic, Office supplies

Key technical data (ASTM)

- Density: 1.14 g/cm³

- Mold Shrinkage: 0.4 – 0.7% (Flow, 2mm)

- Tensile Strength: 52 MPa

- Elongation at Break: 50%

- Flexural Strength: 75 MPa

- Flexural Modulus: 2000 MPa

- Impact Strength (IZOD Notched): 55 KJ/m² (23°C, 3.2mm)

- Heat Deflection Temp (HDT): 103°C (@ 1.8 MPa, 3.2mm)

- Melt Temperature: ~260°C

- Mold Temperature: ~80°C

- Drying: Essential! 90-100°C for 3+ hours

- Max Processing Temp: 280°C

- Injection Pressure: 60-100 MPa

- Injection Speed: 50-80%

Download

Application

- Electrical & Electronic (E&E): Computer monitor bezels and housings; Printer and copier exteriors and internal components; Power tool housings; Consumer electronics enclosures; Electrical connectors and sockets.

- Office Supplies: Durable casings for staplers, hole punches, tape dispensers; Frames and bodies for desktop organizers; Components for projectors and presentation equipment; Robust housings for calculators and electronic office devices.

Features & Benefits

Related Suke PC/ABS Products

Advanced Manufacturing