Kibisan® PN-127H General Purpose Grade SAN Resin

Kibisan PN-127H SAN Resin is a tough, chemical-resistant plastic.It stands up to drops, cleaners, and heat. Flows smoothly during molding (18 ml/10 min) for clear, strong parts that keep their shape. UL 94 HB safety rated, with competitive pricing. Trusted for high-strength, transparent designs—similar to pn 127h chimei but built to last.

- Manufacturer: CHIMEI

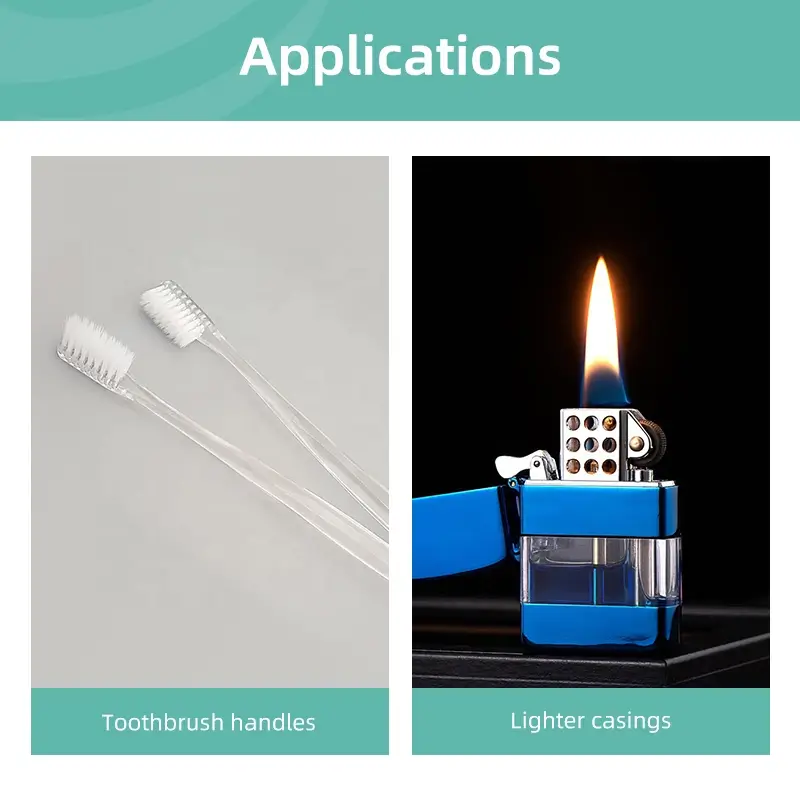

- Application: Toothbrush handles, battery casings, lighter casings, any transparent molded products requiring high strength

- Character: Chemical resistance, high impact strength

Key technical data (ISO)

- Melt Flow Index: 18 ml/10 min (220°C, 10KG)

- Tensile Strength: 79 MPa (high load-bearing capacity)

- Heat Resistance: 91–102°C (distortion temperature)

- Impact Strength: 3 KJ/m² (23°C, notched)

- Flammability Rating: UL 94 HB (safe for consumer goods)

- Mold Shrinkage: 0.2–0.7% (consistent molding results)

Applications

- Toothbrush Handles: Combines clarity with break-resistant durability.

- Battery Casings: Resists acid leakage and mechanical stress.

- Lighter Casings: Withstands repeated impacts and temperature shifts.

- Transparent Molded Products: Maintains strength and optical clarity for medical or cosmetic packaging.

Kibisan® PN-127H Datasheet

| General SAN KIBISAN® PN-127H | ||||

| Product Description: Chemcial resistant | ||||

| Properties | ISO Test Method | Test Condition | Unit | PN-127H |

| Melt Flow Index | 1133 | 220℃×10KG | ml/10 min | 18 |

| Mass Density | 1183 | 23 ℃ | g/cm3 | 1.06 |

| Tensile Strength | 527 | 50 mm/min, yield | MPa | 79 |

| 50 mm/min, break | MPa | 79 | ||

| Tensile Elongation | 527 | 50 mm/min | % | 3 |

| Flexural Strength | 178 | 2 mm/min | MPa | 109 |

| Flexural Modulus | 178 | 2 mm/min | GPa | 3.6 |

| Izod Impact Strength | 180/1A | 23℃, Notched | KJ/m2 | 3 |

| -30℃, Notched | KJ/m2 | – | ||

| Charpy Impact Strength | 179 | 23℃, Notched | KJ/m2 | 3 |

| -30℃, Notched | KJ/m2 | – | ||

| Vicat Softening Temp. | 306 | 50℃/hr;1KG | ℃ | 107 |

| 50℃/hr;5KG | ℃ | 104 | ||

| Heat Distortion Temp. | 75/A | 1.8MPa, unannealed | ℃ | 91 |

| 1.8MPa, annealed | ℃ | 102 | ||

| Coefficient of Linear Thermal Expansion | 11359 | – | – | 3.6~3.8*10-5 |

| Flammability | – | UL-94 | – | 1.5mm HB |

| Mold Shrinkage | 294-4 | – | % | 0.2~0.7 |

| Symbol | 1043 | – | – | >SAN< |

| March 11, 2024 | ||||

Kibisan® PN-127H UL Product iQ

| KIBISAN® PN-127H UL Product iQ | ||

| File Number: E56070 | Yellow Card™ | Styrene Acrylonitrile (SAN) “KIBISAN”, furnished as pellets |

| FLAMMABILITY PROPERTIES | VALUE | TEST METHOD |

| Flammability | ANSI/UL 94 | |

| 1.5 mm, Color: ALL | HB | |

| 3.0 mm, Color: ALL | HB | |

| ISO/IEC FLAMMABILITY PROPERTIES | VALUE | TEST METHOD |

| Flammability | IEC 60695-11-10 | |

| 1.5 mm, Color: ALL | HB75 | |

| 3.0 mm, Color: ALL | HB40 | |

| ELECTRICAL PROPERTIES | VALUE | TEST METHOD |

| Hot-wire Ignition (HWI) | PLC 0 | UL 746A |

| (1.5 mm) | ||

| High Amp Arc Ignition (HAI) | PLC 0 | UL 746A |

| (1.5 mm) | ||

| High Voltage Arc Tracking Rate (HVTR) | PLC 0 | |

| High Voltage, Low Current Arc Resistance | PLC 6 | |

| THERMAL PROPERTIES | VALUE | TEST METHOD |

| Relative Thermal Index – Electrical Strength | UL 746B | |

| 1.5 mm | 50 °C | |

| 3.0 mm | 50 °C | |

| Relative Thermal Index – Mechanical Impact | UL 746B | |

| 1.5 mm | 50 °C | |

| 3.0 mm | 50 °C | |

| Relative Thermal Index – Mechanical Strength | UL 746B | |

| 1.5 mm | 50 °C | |

| 3.0 mm | 50 °C | |

| Report Date: 1983-05-12 | ||

| Relative Thermal Index – Mechanical Strength | UL 746B | |

| 1.5 mm | 50 °C | |

| 3.0 mm | 50 °C | |

Related Kibisan® SAN (aS) Plastics

Chimei Kibisan® PN-137H SAN

Chimei Kibisan® PN-127 L150FG

Chimei Kibisan® PN-127 L200

Chimei Kibisan® PN-127 L150

Chimei Kibisan® PN-117H L150FG

Chimei Kibisan® PN-117C

Chimei Kibisan® PN-117 L100

Chimei Kibisan® PN-106 L150

Chimei Kibisan® PN-127H SAN

Chimei Kibisan® PN-107 L125 SAN

Chimei Kibisan® PN-117 L200 SAN

Chimei Kibisan® PN-127 L100

Chimei Kibisan® PN-107 L125FG

Advanced Manufacturing