Chimei Kibisan® PN-137H General Purpose Grade

KIBISAN PN-137H is a high-strength SAN resin engineered for superior chemical resistance and durability. Ideal for precision-molded industrial components. This General SAN resin solves critical pain points: cracking under chemical exposure, warping in heat, and costly part replacements. Its balanced properties make it a cost-effective, reliable choice for manufacturers prioritizing safety and longevity.

- Character: High strength, high chemical resistance

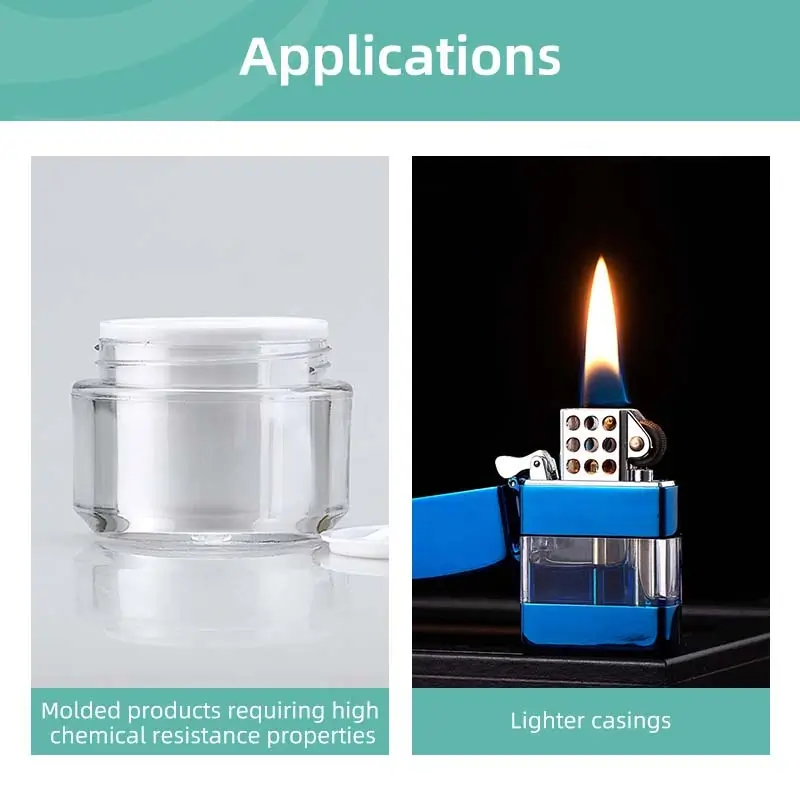

- Application: Lighters, molded products requiring high chemical resistance properties

Key technical data (ISO)

- Tensile Strength: 83 MPa

- Flexural Strength: 123 MPa

- Impact Strength (Izod, 23°C): 3 KJ/m²

- Heat Distortion Temp (1.8MPa): 91–102°C

- Vicat Softening Temp: 108°C

- Melt Flow Index: 12 ml/10 min (easy molding)

- Flammability: UL 94 HB (self-extinguishing)

- Mold Shrinkage: 0.2–0.7% (dimensional accuracy)

- Compliance: UL-certified (File E56070), IEC/ISO standards

Applications

- Lighters: Withstands fuel exposure and high-temperature flames.

- Chemical-Resistant Components: Valves, pump parts, and lab equipment housings.

- Consumer Goods: Durable cosmetic cases, appliance knobs, and housings.

- Electrical Enclosures: Safe, non-conductive, and heat-resistant.

Kibisan® PN-137H Datasheet

| General SAN KIBISAN® PN-137H Product Description: High strength Chemcial resistant | ||||

| Properties | ISO Test Method | Test Condition | Unit | PN-137H |

| Melt Flow Index | 1133 | 220℃×10KG | ml/10 min | 12 |

| Mass Density | 1183 | 23 ℃ | g/cm3 | 1.06 |

| Tensile Strength | 527 | 50 mm/min, yield | MPa | 83 |

| 50 mm/min, break | MPa | 83 | ||

| Tensile Elongation | 527 | 50 mm/min | % | 3 |

| Flexural Strength | 178 | 2 mm/min | MPa | 123 |

| Flexural Modulus | 2 mm/min | GPa | 4 | |

| Izod Impact Strength | 180/1A | 23℃, Notched | KJ/m2 | 3 |

| -30℃, Notched | KJ/m2 | |||

| Charpy Impact Strength | 179 | 23℃, Notched | KJ/m2 | 3 |

| -30℃, Notched | KJ/m2 | – | ||

| Vicat Softening Temp. | 306 | 50℃/hr;1KG | ℃ | 108 |

| 50℃/hr;5KG | ℃ | 105 | ||

| Heat Distortion Temp. | 75/A | 1.8MPa, unannealed | ℃ | 91 |

| 1.8MPa, annealed | ℃ | 102 | ||

| Coefficient of Linear Thermal Expansion | 11359 | – | – | 3.6~3.8*10-5 |

| Flammability | – | UL-94 | – | 1.5mm HB |

| Mold Shrinkage | 294-4 | – | % | 0.2~0.7 |

| Symbol | 1043 | – | – | >SAN< |

| March 11, 2024 Notes:These are typical properties only and are not to be construed as specifications. Users should confirm results by their own test | ||||

Kibisan® PN-137H UL Product iQ

| KIBISAN® PN-137H | UL Product iQ | ||

| File Number: E56070 | Yellow Card™ | Acrylonitrile Butadiene Styrene (ABS) “POLYLAC”, furnished as pellets |

| FLAMMABILITY PROPERTIES | VALUE | TEST METHOD |

| Flammability | ANSI/UL 94 | |

| 1.5 mm, Color: ALL | HB | |

| 3.0 mm, Color: ALL | HB | |

| ISO/IEC FLAMMABILITY PROPERTIES | VALUE | TEST METHOD |

| Flammability | IEC 60695-11-10 | |

| 1.5 mm, Color: ALL | HB75 | |

| 3.0 mm, Color: ALL | HB40 | |

| ELECTRICAL PROPERTIES | VALUE | TEST METHOD |

| Hot-wire Ignition (HWI) | UL 746A | |

| 1.5 mm | PLC 3 | |

| 3.0 mm | PLC 2 | |

| High Amp Arc Ignition (HAI) | UL 746A | |

| 1.5 mm | PLC 0 | |

| 3.0 mm | PLC 0 | |

| Comparative Tracking Index (CTI) | PLC 1 | UL 746A |

| High Voltage Arc Tracking Rate (HVTR) | PLC 0 | |

| High Voltage, Low Current Arc Resistance | PLC 4 | |

| THERMAL PROPERTIES | VALUE | TEST METHOD |

| Relative Thermal Index – Electrical Strength | UL 746B | |

| 1.5 mm | 50 °C | |

| 3.0 mm | 50 °C | |

| Relative Thermal Index – Mechanical Impact | UL 746B | |

| 1.5 mm | 50 °C | |

| 3.0 mm | 50 °C | |

| Relative Thermal Index – Mechanical Strength | UL 746B | |

| 1.5 mm | 50 °C | |

| 3.0 mm | 50 °C | |

Related Kibisan® SAN (aS) Plastics

Chimei Kibisan® PN-127 L150FG

Chimei Kibisan® PN-127 L200

Chimei Kibisan® PN-127 L150

Chimei Kibisan® PN-117H L150FG

Chimei Kibisan® PN-117C

Chimei Kibisan® PN-117 L100

Chimei Kibisan® PN-106 L150

Chimei Kibisan® PN-127H SAN

Chimei Kibisan® PN-107 L125 SAN

Chimei Kibisan® PN-117 L200 SAN

Chimei Kibisan® PN-127 L100

Chimei Kibisan® PN-107 L125FG

Advanced Manufacturing