Polylac® PA-765A Flame Retardant High Flow ABS Resin

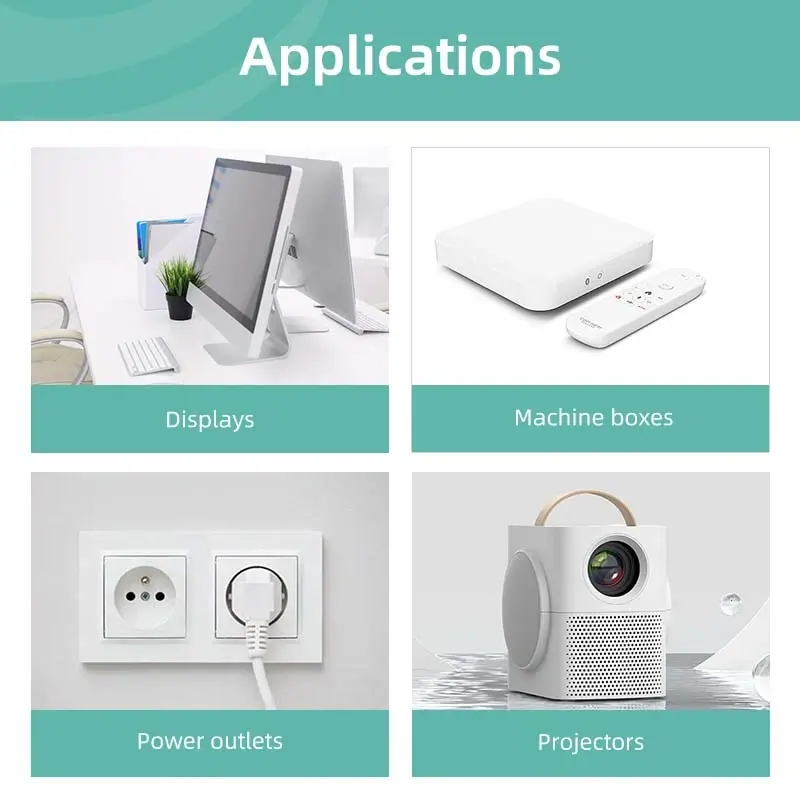

POLYLAC PA-765A is a flame-retardant ABS resin. It meets strict fire standards (UL94 V-0 at 2.1mm, 5VA at 2.5mm), ideal for electronics, car parts, and appliances. Its high flow (48 ml/10min) fills complex molds smoothly, perfect for thin walls like power outlets or printer casings. Durable against impacts (22 kJ/m²) and heat (up to 93°C), it’s trusted for coffee machines, TV frames, and more. UL-certified and Yellow Card-compliant. For details, check the PA-765A datasheet.

- Manufacturer: CHIMEI

- Character: High flowability, 1.5mm V-1, 2.1mm V-0, 2.1mm 5VB, 2.5mm 5VA (TBBA series)

Download

Access essential product documentation including technical datasheets, safety information, environmental certifications, and processing guides.

All documents are sourced directly from manufacturers and updated regularly for accuracy.

Polylac® PA-765A Datasheet

| Flame Retardant ABS POLYLAC® PA-765A | ||||

| Product Description: F.R. High flow | ||||

| Properties | ISO Test Method | Test Condition | Unit | PA-765A |

| Melt Flow Index | 1133 | 220℃×10KG | ml/10 min | 48 |

| Mass Density | 1183 | 23 ℃ | g/cm3 | 1.17 |

| Tensile Strength | 527 | 50 mm/min, yield | MPa | 39 |

| 50 mm/min, break | MPa | 29 | ||

| Tensile Elongation | 527 | 50 mm/min | % | 10 |

| Flexural Strength | 178 | 2 mm/min | MPa | 56 |

| Flexural Modulus | 178 | 2 mm/min | GPa | 1.8 |

| Izod Impact Strength | 180/1A | 23℃, Notched | KJ/m2 | 22 |

| -30℃, Notched | KJ/m2 | 10 | ||

| Charpy Impact Strength | 179 | 23℃, Notched | KJ/m2 | 23 |

| -30℃, Notched | KJ/m2 | 10 | ||

| Vicat Softening Temp. | 306 | 50℃/hr;1KG | ℃ | 93 |

| 50℃/hr;5KG | ℃ | 79 | ||

| Heat Distortion Temp. | 75/A | 1.8MPa, unannealed | ℃ | 76 |

| 1.8MPa, annealed | ℃ | 84 | ||

| Coefficient of Linear Thermal Expansion | 11359 | – | – | 8.48 x 10-5 |

| Flammability | – | UL-94 | – | 1.5mm V-1 |

| 2.1mm V-0 | ||||

| 2.1mm 5VB | ||||

| 2.5mm 5VA | ||||

| Mold Shrinkage | 294-4 | – | % | 0.3~0.6 |

| Symbol | 1043 | – | – | >ABS-FR(17)< |

| March 11, 2024 | ||||

Polylac® PA-765A UL Product iQ

| POLYLAC® PA-765A UL Product iQ | ||

| File Number: E56070 | Yellow Card™ | Acrylonitrile Butadiene Styrene (ABS) “POLYLAC”, furnished as pellets |

| FLAMMABILITY PROPERTIES | VALUE | TEST METHOD |

| Flammability | ANSI/UL 94 | |

| 1.5 mm, Color: ALL | V-1 | |

| 2.1 mm, Color: ALL | 5VB | |

| V-0 | ||

| 2.5 mm, Color: ALL | 5VA | |

| V-0 | ||

| 3.0 mm, Color: ALL | 5VA | |

| V-0 | ||

| ISO/IEC FLAMMABILITY PROPERTIES | VALUE | TEST METHOD |

| Flammability | IEC 60695-11-10 | |

| 1.5 mm, Color: ALL | V-1 | |

| 2.1 mm, Color: ALL | V-0 | |

| 2.5 mm, Color: ALL | V-0 | |

| 3.0 mm, Color: ALL | V-0 | |

| Flammability | IEC 60695-11-20 | |

| 2.1 mm, Color: ALL | 5VB | |

| 2.5 mm, Color: ALL | 5VA | |

| 3.0 mm, Color: ALL | 5VA | |

| ELECTRICAL PROPERTIES | VALUE | TEST METHOD |

| Hot-wire Ignition (HWI) | UL 746A | |

| 2.1 mm | PLC 3 | |

| 2.5 mm | PLC 3 | |

| 3.0 mm | PLC 0 | |

| High Amp Arc Ignition (HAI) | UL 746A | |

| 2.1 mm | PLC 0 | |

| 2.5 mm | PLC 0 | |

| 3.0 mm | PLC 0 | |

| Comparative Tracking Index (CTI) | PLC 1 | UL 746A |

| High Voltage Arc Tracking Rate (HVTR) | PLC 2 | |

| High Voltage, Low Current Arc Resistance | PLC 7 | |

| THERMAL PROPERTIES | VALUE | TEST METHOD |

| Relative Thermal Index – Electrical Strength | UL 746B | |

| 1.5 mm | 85 °C | |

| 2.1 mm | 85 °C | |

| 2.5 mm | 85 °C | |

| 3.0 mm | 85 °C | |

| Relative Thermal Index – Mechanical Impact | UL 746B | |

| 1.5 mm | 80 °C | |

| 2.1 mm | 80 °C | |

| 2.5 mm | 80 °C | |

| 3.0 mm | 80 °C | |

| Relative Thermal Index – Mechanical Strength | UL 746B | |

| 1.5 mm | 85 °C | |

| 2.1 mm | 85 °C | |

| 2.5 mm | 85 °C | |

| 3.0 mm | 85 °C | |

| Report Date: 1983-06-23 | ||

| 2.5 mm | 80 °C | |

| 3.0 mm | 80 °C | |

Related Polylac® ABS Plastics

Chimei Polylac® PA-763AH ABS

Chimei Polylac® PA-763H ABS

Chimei Polylac® PA-764B

Chimei Polylac® PA-764G

Chimei Polylac® PA-797 ABS

Chimei Polylac® PA-757G J08 ABS

Chimei Polylac® PA-757 J01 ABS

Chimei Polylac® PA-757 A01 ABS

Chimei Polylac® PA-756S ABS

Chimei Polylac® PA-756H ABS

Chimei Polylac® PA-747S A01 ABS

Chimei Polylac® PA-747S ABS

Chimei Polylac® PA-747R ABS

Chimei Polylac® PA-747H ABS

Chimei Polylac® PA-747F ABS

Chimei Polylac® PA-746M ABS

Chimei Polylac® PA-746H ABS

Chimei Polylac® PA-737 A03 ABS

Advanced Manufacturing