WONDERLITE® PC-110 General Purpose grade Resin Medium viscosity Plastic

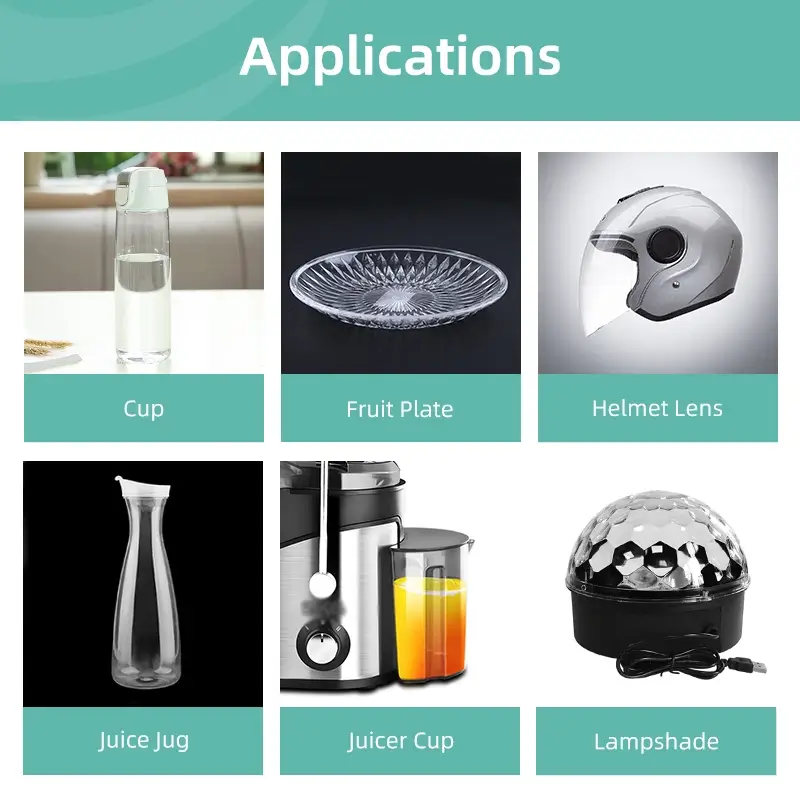

Chimei WONDERLITE® PC-110 is a high-performance polycarbonate resin that delivers exceptional clarity and durability. This versatile PC resin is perfect for injection molding applications where transparency meets strength. From automotive lighting to food containers and fashion accessories, PC-110 offers reliable performance and consistent quality.

- Manufacturer: CHIMEI

- Application: General injection molding for vehicle indicator light casings, chocolate containers, high heel shoes

- Character: Weather and UV resistant formulation, medium viscosity for easy processing

Download

Access essential product documentation including technical data sheets, safety information, environmental certifications, and processing guides.

All documents are sourced directly from manufacturers and updated regularly for accuracy.

WONDERLITE® PC-110 Datasheet

| General PC WONDERLITE® PC-110 | ||||

| Product Description: Medium viscosity | ||||

| Properties | ISO Test Method | Test Condition | Unit | PC-110 |

| Melt Flow Index | 1133 | 300℃ × 1.2KG | ml/10 min | 10 |

| Mass Density | 1183 | 23 ℃ | g/cm3 | 1.2 |

| Tensile Strength | 527 | 50 mm/min, yield | MPa | 65 |

| 50 mm/min, break | MPa | 75 | ||

| Tensile Elongation | 527 | 50 mm/min | % | 120 |

| Flexural Strength | 178 | 2 mm/min | MPa | 90 |

| Flexural Modulus | 178 | 2 mm/min | GPa | 2.4 |

| Izod Impact Strength | 180/1A | 23℃, Notched,1/8″ | KJ/m2 | 75 |

| -30℃, Notched,1/8″ | KJ/m2 | – | ||

| Charpy Impact Strength | 179 | 23℃, Notched | KJ/m2 | 75 |

| -30℃, Notched | KJ/m2 | – | ||

| Vicat Softening Temp. | 306 | 50℃/hr;1KG | ℃ | 150 |

| 50℃/hr;5KG | ℃ | 145 | ||

| Heat Distortion Temp. | 75/A | 1.8MPa, unannealed | ℃ | 128 |

| 1.8MPa, annealed | ℃ | 143 | ||

| Coefficient of Linear Thermal Expansion | 11359 | – | – | 6.0~8.0×10-5 |

| Flammability | – | UL-94 | – | 2.5mm V-2 |

| Mold Shrinkage | 294-4 | – | % | 0.5~0.7 |

| Symbol | 1043 | – | – | >PC< |

| March 11, 2024 | ||||

| Notes:These are typical properties only and are not to be construed as specifications. Users should confirm results by their own test. | ||||

WONDERLITE® PC-110 UL Product iQ

| WONDERLITE® PC-110 UL Product iQ | ||

| File Number: E56070 | Yellow Card™ | Polycarbonate (PC) “WONDERLITE”, furnished as pellets |

| FLAMMABILITY PROPERTIES | VALUE | TEST METHOD |

| Flammability | ANSI/UL 94 | |

| 1.5 mm, Color: ALL | V-2 | |

| 2.5 to 2.8 mm, Color: ALL | V-2 | |

| 3.0 mm, Color: ALL | HB | |

| ISO/IEC FLAMMABILITY PROPERTIES | VALUE | TEST METHOD |

| Flammability | IEC 60695-11-10 | |

| 1.5 mm, Color: ALL | V-2 | |

| 2.5 to 2.8 mm, Color: ALL | V-2 | |

| 3.0 mm, Color: ALL | HB40 | |

| ELECTRICAL PROPERTIES | VALUE | TEST METHOD |

| Hot-wire Ignition (HWI) | UL 746A | |

| 1.5 mm | PLC 2 | |

| 2.5 to 2.8 mm | PLC 2 | |

| 3.0 mm | PLC 2 | |

| High Amp Arc Ignition (HAI) | UL 746A | |

| 1.5 mm | PLC 4 | |

| 2.5 to 2.8 mm | PLC 3 | |

| 3.0 mm | PLC 3 | |

| Comparative Tracking Index (CTI) | PLC 2 | UL 746A |

| High Voltage Arc Tracking Rate (HVTR) | PLC 2 | |

| High Voltage, Low Current Arc Resistance | PLC 6 | |

| THERMAL PROPERTIES | VALUE | TEST METHOD |

| Relative Thermal Index – Electrical Strength | UL 746B | |

| 1.5 mm | 125 °C | |

| 2.5 to 2.8 mm | 125 °C | |

| 3.0 mm | 125 °C | |

| Relative Thermal Index – Mechanical Impact | UL 746B | |

| 1.5 mm | 105 °C | |

| 2.5 to 2.8 mm | 105 °C | |

| 3.0 mm | 105 °C | |

| Relative Thermal Index – Mechanical Strength | UL 746B | |

| 1.5 mm | 125 °C | |

| 2.5 to 2.8 mm | 125 °C | |

| 3.0 mm | 125 °C | |

| Report Date: 2001-09-25 | ||

Related WONDERLITE® PC Plastics

Chimei WONDERLITE® PC-6715NF

Chimei WONDERLITE® PC-6710NF

Chimei WONDERLITE® PC-6700

Chimei WONDERLITE® PC-6715VT

Chimei WONDERLITE® PC-6600 J01

Chimei WONDERLITE® PC-681U

Chimei WONDERLITE® PC-616LS

Chimei WONDERLITE® PC-175

Chimei WONDERLITE® PC-145K

Chimei WONDERLITE® PC-122P

Chimei WONDERLITE® PC-115U

Chimei WONDERLITE® PC-115

Chimei WONDERLITE® PC-115L

Chimei WONDERLITE® PC-110P

Chimei WONDERLITE® PC-110L

Chimei WONDERLITE® PC-108U

Chimei WONDERLITE® PC-6610

Chimei WONDERLITE® PC-6710

Chimei WONDERLITE® PC-6600

Chimei WONDERLITE® PC-122u

Chimei WONDERLITE® PC-122

Chimei WONDERLITE® PC-115p

Chimei WONDERLITE® PC-110u

Chimei WONDERLITE® PC-110

Advanced Manufacturing