LG ABS HI121H General Purpose Impact Resistance

LG ABS HI121H is a high-performance, general-purpose ABS resin engineered for superior impact resistance and ease of processing. Ideal for demanding industrial applications like electronics and consumer goods, it combines durability, thermal stability, and UL-certified safety—making it a trusted solution for manufacturers prioritizing reliability and cost-efficiency.

- Character Description: Impact Resistance, General Purpose

Key technical data (ISO)

- Tensile Strength: 46 MPa | Flexural Strength: 70 MPa

- Impact Strength: 20 kJ/m² (23°C) / 10 kJ/m² (-30°C)

- Hardness (Rockwell R): 110

- Heat Resistance: HDT 79°C | Vicat 93°C

- Flammability Rating: UL 94 HB (1.5–3.0mm thickness)

- Electrical Safety: Dielectric Strength 27 kV/mm

- Melt Flow Rate: 22 g/10min | Mold Shrinkage: 0.4–0.7%

- UL RTI Rating: 95–100°C (Electrical/Mechanical)

- Compliant with IEC, ASTM, and ISO standards

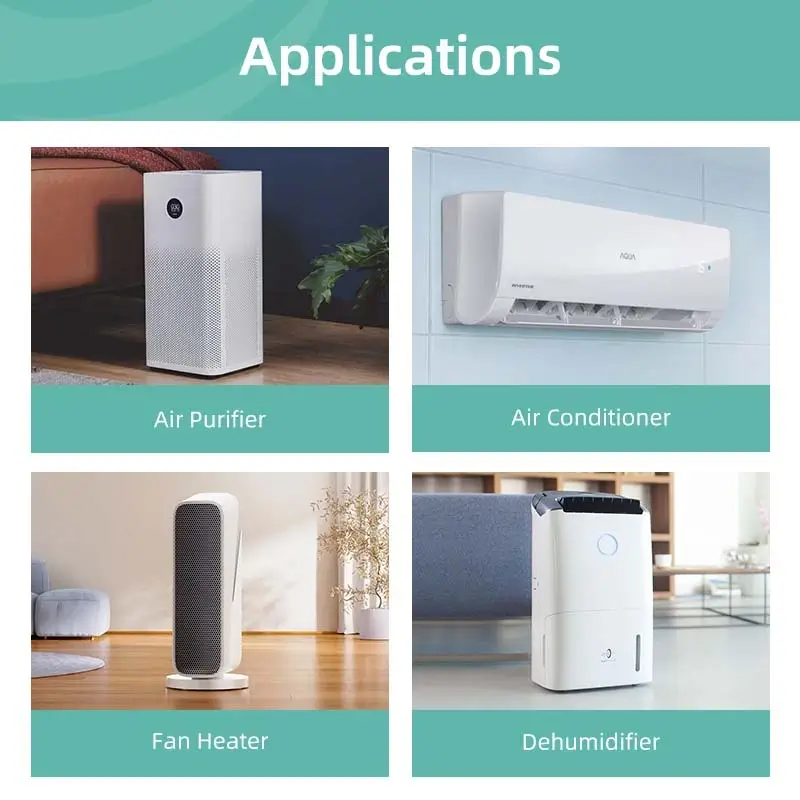

Applications

- Electrical/Electronic Products: Housings for power tools, printers, and small appliances. Connectors, switches, and circuit breaker components. Charger casings resistant to daily wear and tear.

- Miscellaneous Goods: Durable handles for luggage or industrial tools. Automotive interior trim and dashboard parts. Consumer product casings (toys, kitchen gadgets).

LG HI121H Datasheet (iSO)

| LG Chem ABS HI121H Product Description: Impact Resistance, General Purpose | ||||

| Properties | Condition | Method | Unit | Model: HI121H |

| Physical Properties | ||||

| Specific Gravity | 23°C | ISO | – | 1.05 |

| Mold Shrinkage | 23°C, 3.2mm | ISO | % | 0.4 – 0.7 |

| Melt Flow Rate | 220°C, 10kg | ISO | g/10min | 22 |

| Mechanical Properties | ||||

| Tensile Strength at Yield | 23°C, 50mm/min, 4mm | ISO | MPa | 46 |

| Tensile Elongation at Break | 23°C, 50mm/min, 4mm | ISO | %, (Min) | 10 |

| Flexural Strength | 23°C, 2mm/min, 4mm | ISO | MPa | 70 |

| Flexural Modulus | 23°C, 2mm/min, 4mm | ISO | MPa | 2300 |

| Izod Impact Strength | Notched, 4mm, 23°C | ISO | kJ/m² | 20 |

| Izod Impact Strength | Notched, 4mm, -30°C | ISO | kJ/m² | 10 |

| Charpy Impact Strength | Notched, 4mm, 23°C | ISO | kJ/m² | 20 |

| Charpy Impact Strength | Notched, 4mm, -30°C | ISO | kJ/m² | 10 |

| Rockwell Hardness | R – Scale | ISO | – | 110 |

| Thermal Properties | ||||

| Heat Deflection Temperature | Flatwise, 1.8MPa, 4mm, Unannealed | ISO | °C | 79 |

| Vicat Softening Temperature | 50N, 50°C/h | ISO | °C | 93 |

LG HI121H UL Product iQ

| LG Chem ABS HI121H | UL Product iQ | ||

| File Number: E67171 | Acrylonitrile Butadiene Styrene (ABS), pellets | |

| Flammability | Value | Test Method |

| Flame Rating | HB | UL 94 |

| Flame Rating | HB | UL 94 |

| Flame Rating | HB40 | IEC 60695-11-10, -20 |

| Flame Rating | HB75 | IEC 60695-11-10, -20 |

| Electrical | Value | Test Method |

| Hot-wire Ignition (HWI) | PLC 3 | UL 746 |

| Hot-wire Ignition (HWI) | PLC 3 | UL 746 |

| High Amp Arc Ignition (HAI) | PLC 0 | UL 746 |

| High Amp Arc Ignition (HAI) | PLC 1 | UL 746 |

| Comparative Tracking Index (CTI) | PLC 0 | UL 746 |

| Dielectric Strength | 27 kV/mm | ASTM D149 |

| High Voltage Arc Tracking Rate (HVTR) | PLC 2 | UL 746 |

| Volume Resistivity | 1.0E+15 Ω·cm | ASTM D257, IEC 60093 |

| Arc Resistance | PLC 6 | ASTM D495 |

| Thermal | Value | Test Method |

| RTI Elec | 95.0 °C | UL 746 |

| RTI Elec | 100 °C | UL 746 |

| RTI Imp | 95.0 °C | UL 746 |

| RTI Imp | 100 °C | UL 746 |

| RTI Str | 95.0 °C | UL 746 |

| RTI Str | 100 °C | UL 746 |

| Physical | Value | Test Method |

| Dimensional Stability | 0 | ASTM D1042, ISO 2796 |

Related LG Chem ABS Plastics

LG Chem ABS XR630

LG Chem ABS XR474

LG Chem ABS XR490

LG Chem ABS XR470

LG Chem ABS XR440

LG Chem ABS XR438

LG Chem ABS XR410

LG Chem ABS XR409H

LG Chem ABS XR404T

LG Chem ABS XR404

LG Chem ABS XR401

LG Chem ABS XR401B

LG Chem ABS NF424

LG Chem ABS ER468

LG Chem ABS ER460

LG Chem ABS ER400-M

LG Chem ABS ER400-C

LG Chem ABS ER400

Advanced Manufacturing