Polylac® PA-746M High Flow Grade Easy Molding ABS

POLYLAC PA-746M is a high-flow ABS resin engineered for large, complex parts requiring flawless painting. With exceptional processability and adhesion, it’s ideal for automotive and consumer goods. Whether you’re molding automotive parts or consumer goods, this resin ensures efficiency without compromise.

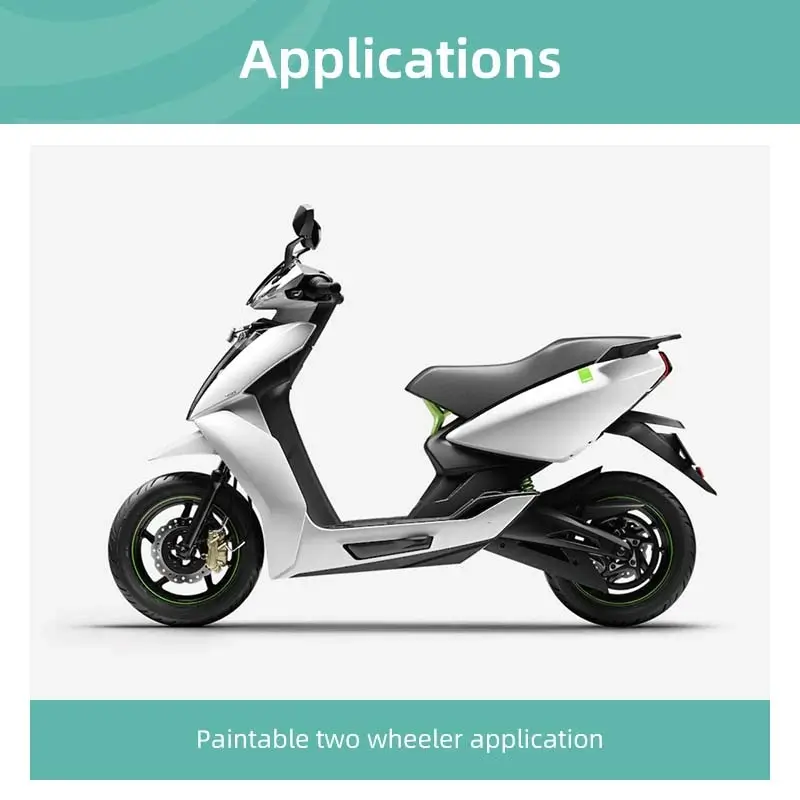

- Application: Paintable two wheeler application

- Character: High flowability, high impact strength

Key technical data (ISO)

- Melt Flow Index: 50 ml/10 min

- Tensile Strength (Yield): 41 MPa

- Izod Impact (23°C): 19 KJ/m²

- Vicat Softening Temp.: 104°C (1KG load)

- Mold Shrinkage: 0.4–0.7%

- Flammability Rating: UL94 HB (1.5mm)

- Certifications: UL Recognized

Applications

- Motorcycle fairings and side panels.

- Scooter body kits with glossy finishes.

- Helmets and visors requiring scratch-resistant coatings.

- All-terrain vehicle (ATV) trim and fenders.

Polylac® PA-746M Datasheet

| Painting ABS POLYLAC® PA-746M Product Description: Excellent Processability and Adhesion Properties | ||||

| Properties | ISO Test Method | Test Condition | Unit | PA-746M |

| Melt Flow Index | 1133 | 220℃×10KG | ml/10 min | 50 |

| Mass Density | 1183 | 23 ℃ | g/cm3 | 1.04 |

| Tensile Strength | 527 | 50 mm/min, yield | MPa | 41 |

| 50 mm/min, break | MPa | 30 | ||

| Tensile Elongation | 527 | 50 mm/min | % | 50 |

| Flexural Strength | 178 | 2 mm/min | MPa | 61 |

| Flexural Modulus | 2 mm/min | GPa | 2.1 | |

| Izod Impact Strength | 180/1A | 23℃, Notched | KJ/m2 | 19 |

| -30℃, Notched | KJ/m2 | – | ||

| Charpy Impact Strength | 179 | 23℃, Notched | KJ/m2 | 20 |

| -30℃, Notched | KJ/m2 | – | ||

| Vicat Softening Temp. | 306 | 50℃/hr;1KG | ℃ | 104 |

| 50℃/hr;5KG | ℃ | 99 | ||

| Heat Distortion Temp. | 75/A | 1.8MPa, unannealed | ℃ | – |

| 1.8MPa, annealed | ℃ | 96 | ||

| Coefficient of Linear Thermal Expansion | 11359 | – | – | 8.3 x 10-5 |

| Flammability | – | UL-94 | – | 1.5mm HB |

| Mold Shrinkage | 294-4 | – | % | 0.4~0.7 |

| Symbol | 1043 | – | – | >ABS< |

| March 12, 2025 Notes:These are typical properties only and are not to be construed as specifications. Users should confirm results by their own test | ||||

Polylac® PA-746M UL Product iQ

| POLYLAC® PA-746M | UL Product iQ | ||

| File Number: E56070 | Yellow Card™ | Acrylonitrile Butadiene Styrene (ABS) “POLYLAC”, furnished as pellets |

| FLAMMABILITY PROPERTIES | VALUE | TEST METHOD |

| Flammability | ANSI/UL 94 | |

| 1.5 mm, Color: ALL | HB | |

| 3.0 mm, Color: ALL | HB | |

| ISO/IEC FLAMMABILITY PROPERTIES | VALUE | TEST METHOD |

| Flammability | IEC 60695-11-10 | |

| 1.5 mm, Color: ALL | HB75 | |

| 3.0 mm, Color: ALL | HB40 | |

| ELECTRICAL PROPERTIES | VALUE | TEST METHOD |

| Hot-wire Ignition (HWI) | UL 746A | |

| 1.5 mm | PLC 5 | |

| 3.0 mm | PLC 5 | |

| High Amp Arc Ignition (HAI) | UL 746A | |

| 1.5 mm | PLC 1 | |

| 3.0 mm | PLC 1 | |

| Comparative Tracking Index (CTI) | PLC 1 | UL 746A |

| High Voltage Arc Tracking Rate (HVTR) | PLC 3 | |

| High Voltage, Low Current Arc Resistance | PLC 7 | |

| THERMAL PROPERTIES | VALUE | TEST METHOD |

| Relative Thermal Index – Electrical Strength | UL 746B | |

| 1.5 mm | 60 °C | |

| 3.0 mm | 60 °C | |

| Relative Thermal Index – Mechanical Impact | UL 746B | |

| 1.5 mm | 60 °C | |

| 3.0 mm | 60 °C | |

| Relative Thermal Index – Mechanical Strength | UL 746B | |

| 1.5 mm | 60 °C | |

| 3.0 mm | 60 °C | |

Related Polylac® ABS Plastics

Chimei Polylac® PA-726M ABS

Chimei Polylac® PA-717C ABS

Chimei POLYLAC® PA-709P ABS

Chimei Polylac® PA-707 ABS

Chimei Polylac® PA-77NB ABS

Chimei Polylac® PA-757H ABS

Chimei Polylac® PA-737 ABS

Chimei Polylac® PA-777E ABS

Chimei Polylac® PA-777D ABS

Chimei Polylac® PA-777B ABS

Chimei Polylac® PA-765B ABS

Chimei Polylac® PA-765A ABS

Chimei Polylac® PA-765 ABS

Chimei Polylac® PA-764 ABS

Chimei Polylac® PA-757F ABS

Chimei Polylac® PA-763 ABS

Chimei Polylac® PA-757 AB

Chimei Polylac® PA-757

Advanced Manufacturing