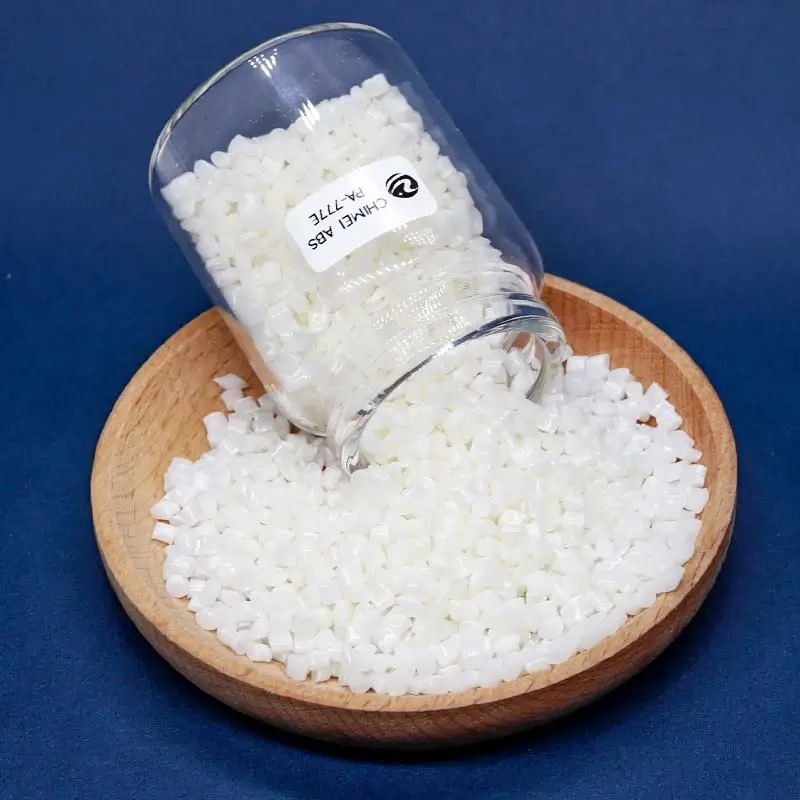

Polylac® PA-777E High Heat Moderate Impact ABS Resin

Polylac PA-777E ABS Resin is a heat-resistant material for tough jobs. It handles heat up to 129°C (Vicat) without warping and stays strong in cold (-30°C) with 12 KJ/m² impact. Easy to mold (4.5 melt flow) and stable (0.3–0.6% shrinkage), it reduces errors. UL94 HB rated for safety. Chimei’s PA-777E offers durability and ease for products that last.

- Manufacturer: CHIMEI

- Application: Shells for heat producing household appliances, hair dryer tubes, iron casings, heaters, auto parts, water tank covers

- Character: Ultra-high heat resistance, moderate impact strength

Key technical data (ISO)

- Vicat Softening Temp: 129°C (1KG load)

- Heat Distortion Temp (HDT): 101°C (unannealed) / 121°C (annealed)

- Tensile Strength: 45 MPa (Yield)

- Flexural Modulus: 2.3 GPa

- Izod Impact (23°C): 12 KJ/m²

- Flammability Rating: UL94 HB (1.5mm thickness)

- Mold Shrinkage: 0.3–0.6%

Applications

- Shells for ovens, heaters, and hair dryers

- Automotive under-hood components (e.g., sensor housings)

- Durable water tank covers and pump parts

- Iron casings and small appliance housings

Polylac® PA-777E Datasheet

| High Heat ABS POLYLAC® PA-777E | ||||

| Product Description: Ultra High heat | ||||

| Properties | ISO Test Method | Test Condition | Unit | PA-777E |

| Melt Flow Index | 1133 | 220℃×10KG | ml/10 min | 4.5 |

| Mass Density | 1183 | 23 ℃ | g/cm3 | 1.07 |

| Tensile Strength | 527 | 50 mm/min, yield | MPa | 45 |

| 50 mm/min, break | MPa | 32 | ||

| Tensile Elongation | 527 | 50 mm/min | % | 25 |

| Flexural Strength | 178 | 2 mm/min | MPa | 74 |

| Flexural Modulus | 178 | 2 mm/min | GPa | 2.3 |

| Izod Impact Strength | 180/1A | 23℃, Notched | KJ/m2 | 12 |

| -30℃, Notched | KJ/m2 | 6 | ||

| Charpy Impact Strength | 179 | 23℃, Notched | KJ/m2 | 13 |

| -30℃, Notched | KJ/m2 | 6 | ||

| Vicat Softening Temp. | 306 | 50℃/hr;1KG | ℃ | 129 |

| 50℃/hr;5KG | ℃ | 121 | ||

| Heat Distortion Temp. | 75/A | 1.8MPa, unannealed | ℃ | 101 |

| 1.8MPa, annealed | ℃ | 121 | ||

| Coefficient of Linear Thermal Expansion | 11359 | – | – | 8.2 x 10-5 |

| Flammability | – | UL-94 | – | 1.5mm HB |

| Mold Shrinkage | 294-4 | – | % | 0.3~0.6 |

| Symbol | 1043 | – | – | >ABS< |

| March 11, 2024 | ||||

Polylac® PA-777E UL Product iQ

| POLYLAC® PA-777E UL Product iQ | ||

| File Number: E56070 | Yellow Card™ | Acrylonitrile Butadiene Styrene (ABS) “POLYLAC”, furnished as pellets |

| FLAMMABILITY PROPERTIES | VALUE | TEST METHOD |

| Flammability | ANSI/UL 94 | |

| 1.5 mm, Color: ALL | HB | |

| 3.0 mm, Color: ALL | HB | |

| ISO/IEC FLAMMABILITY PROPERTIES | VALUE | TEST METHOD |

| Flammability | IEC 60695-11-10 | |

| 1.5 mm, Color: ALL | HB75 | |

| 3.0 mm, Color: ALL | HB40 | |

| ELECTRICAL PROPERTIES | VALUE | TEST METHOD |

| Hot-wire Ignition (HWI) | UL 746A | |

| 1.5 mm | PLC 4 | |

| 3.0 mm | PLC 4 | |

| High Amp Arc Ignition (HAI) | UL 746A | |

| 1.5 mm | PLC 0 | |

| 3.0 mm | PLC 0 | |

| Comparative Tracking Index (CTI) | PLC 0 | UL 746A |

| High Voltage Arc Tracking Rate (HVTR) | PLC 1 | |

| High Voltage, Low Current Arc Resistance | PLC 6 | |

| THERMAL PROPERTIES | VALUE | TEST METHOD |

| Relative Thermal Index – Electrical Strength | UL 746B | |

| 1.5 mm | 50 °C | |

| 3.0 mm | 50 °C | |

| Relative Thermal Index – Mechanical Impact | UL 746B | |

| 1.5 mm | 50 °C | |

| 3.0 mm | 50 °C | |

| Relative Thermal Index – Mechanical Strength | UL 746B | |

| 1.5 mm | 50 °C | |

| 3.0 mm | 50 °C | |

Related Polylac® ABS Plastics

Chimei Polylac® PA-763AH ABS

Chimei Polylac® PA-763H ABS

Chimei Polylac® PA-764B

Chimei Polylac® PA-764G

Chimei Polylac® PA-797 ABS

Chimei Polylac® PA-757G J08 ABS

Chimei Polylac® PA-757 J01 ABS

Chimei Polylac® PA-757 A01 ABS

Chimei Polylac® PA-756S ABS

Chimei Polylac® PA-756H ABS

Chimei Polylac® PA-747S A01 ABS

Chimei Polylac® PA-747S ABS

Chimei Polylac® PA-747R ABS

Chimei Polylac® PA-747H ABS

Chimei Polylac® PA-747F ABS

Chimei Polylac® PA-746M ABS

Chimei Polylac® PA-746H ABS

Chimei Polylac® PA-737 A03 ABS

Chimei Polylac® PA-726M ABS

Chimei Polylac® PA-717C ABS

Chimei POLYLAC® PA-709P ABS

Chimei Polylac® PA-707 ABS

Chimei Polylac® PA-77NB ABS

Chimei Polylac® PA-757H ABS

Chimei Polylac® PA-737 ABS

Chimei Polylac® PA-777E ABS

Chimei Polylac® PA-777D ABS

Chimei Polylac® PA-777B ABS

Chimei Polylac® PA-765B ABS

Chimei Polylac® PA-765A ABS

Advanced Manufacturing