TAIRILAC® AG15A1-H ABS Resin General Grade

TAIRILAC AG15A1-H ABS Resin (by Formosa) is a high-gloss, medium-impact plastic perfect for toys, phone cases, luggage, and electronics. It handles heat up to 94°C, stays strong under stress (45MPa tensile, 68MPa flexural), and molds smoothly with low shrinkage (0.4–0.7%). The HB flammability rating ensures safety for household items. Durable, heat-resistant, and easy to shape—ideal for sleek, reliable designs.

- Character: High gloss, Medium impact

Key technical data (ISO)

- Melt Flow Index: 21 g/10 min (220°C/10kg) | Specific Gravity: 1.05 (lightweight)

- Heat Resistance: Vicat Softening Point @94°C | HDT @90°C (1.8MPa)

- Mechanical Strength: Tensile Strength @45 MPa | Flexural Strength @68 MPa

- Molding Shrinkage: 0.4–0.7% (consistent dimensional stability)

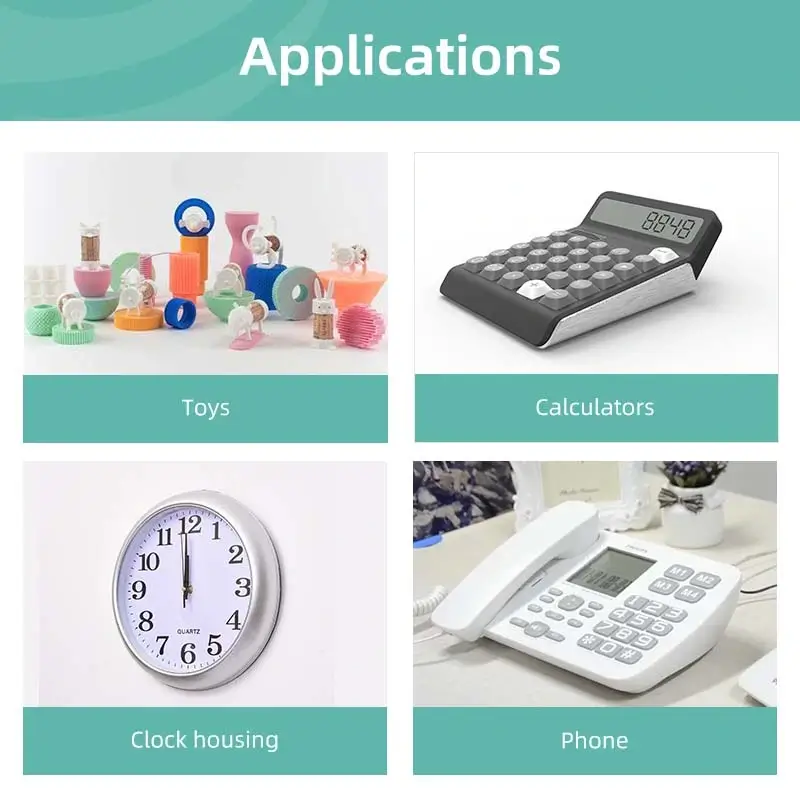

Application

- Toys: Medium impact strength withstands drops, while high gloss retains vibrant colors.

- Phone/Stereo Housings: Scratch-resistant surfaces stay pristine through daily use.

- Calculators/Clocks: Smooth molding ensures crisp edges and flawless finishes.

- Suitcases: Lightweight yet tough construction resists cracks during travel.

Tairilac® AG15A1-H Datasheet

| General grade FCFC TAIRILAC® AG15A1-H Data Sheet | ||||

| Product Description: High gloss, Medium impact | ||||

| Property | Unit | Test Method | Test Condition | General Grade |

| Melt Flow Index | g/10 min | ISO 1133 | 200℃ × 5kg | 2.2 |

| Melt Flow Index | g/10 min | ISO 1133 | 220℃ × 10kg | 21 |

| Specific Gravity | – | ISO 1183 | 23℃/23℃ | 1.05 |

| Tensile Strength | Mpa | ISO 527 | 23℃, 50mm/min | 45 |

| Flexural Strength | Mpa | ISO 178 | 23℃, 2mm/min | 68 |

| Flexural Modulus | Mpa | ISO 178 | 23℃, 2mm/min | 2400 |

| Rockwell Hardness | R-scale | ISO 2039-2 | 23℃ | R-110 |

| Vicat Softening Point | ℃ | ISO 306 | Annealed, 50N,50℃/h | 94 |

| Heat Deflection Temperature | ℃ | ISO 75/A | Annealed, 1.8Mpa 4mm thick,120℃/h | 90 |

| Molding Shrinkage | % | ISO 2577 | 3.2mm | 0.4 ~ 0.7 |

| Combustibility | UL-94 | File No. E162823 | HB 1 ~ 3 mm | |

Tairilac® AG15A1-H UL Product iQ

| TAIRILAC® ANC160 UL Product iQ | ||

| File Number: E162823 | Acrylonitrile Butadiene Styrene (ABS), pellets | |

| Flammability | Value | Test Method |

| Flame Rating | ||

| 1.0 mm, ALL | HB | UL 94 |

| 1.5 mm, ALL | HB | UL 94 |

| 3.0 mm, ALL | HB | UL 94 |

| 3.0 mm, ALL | HB40 | IEC 60695-11-10, -20 |

| 1.0 mm, ALL | HB75 | IEC 60695-11-10, -20 |

| 1.5 mm, ALL | HB75 | IEC 60695-11-10, -20 |

| Electrical | Value | Test Method |

| Hot-wire Ignition (HWI) | UL 746 | |

| 1.0 mm | PLC 4 | |

| 1.5 mm | PLC 4 | |

| 3.0 mm | PLC 3 | |

| High Amp Arc Ignition (HAI) | UL 746 | |

| 1.0 mm | PLC 0 | |

| 1.5 mm | PLC 0 | |

| 3.0 mm | PLC 0 | |

| Comparative Tracking Index (CTI) | PLC 0 | UL 746 |

| High Voltage Arc Tracking Rate (HVTR) | PLC 2 | UL 746 |

| Arc Resistance | PLC 6 | ASTM D495 |

| Thermal | Value | Test Method |

| RTI Elec | UL 746 | |

| 1.0 mm | 60.0°C | |

| 1.5 mm | 75.0°C | |

| 3.0 mm | 95.0°C | |

| RTI Imp | UL 746 | |

| 1.0 mm | 60.0°C | |

| 1.5 mm | 60.0°C | |

| 3.0 mm | 80.0°C | |

| RTI Str | UL 746 | |

| 1.0 mm | 60.0°C | |

| 1.5 mm | 60.0°C | |

| 3.0 mm | 95.0°C | |

Related Tairilac® ABS Plastics

Formosa TAIRILAC® AG20GF ABS

Formosa TAIRILAC® AG16A1

Formosa TAIRILAC® AE10EP ABS

Formosa TAIRILAC® AX4100 ABS

Formosa TAIRILAC® ANC120 ABS

Formosa TAIRILAC® AE8700 ABS

Formosa TAIRILAC® AG10NP ABS

Formosa TAIRILAC® AE8000 ABS

Formosa TAIRILAC® AG10AP ABS

Formosa TAIRILAC® AG23AT ABS

Formosa TAIRILAC® ANC100 ABS

Formosa TAIRILAC® AX4300 ABS

Formosa TAIRILAC® AX4000

Formosa TAIRILAC® AF3535

Formosa TAIRILAC® AF3530 ABS

Formosa TAIRILAC® AF3560 ABS

Formosa TAIRILAC® AF3500 ABS

Formosa TAIRILAC® AG100H ABS

Advanced Manufacturing