TAIRIPRO® K7009 Impact Copolymer Injection Molding

TAIRIPRO K7009 is a high-performance impact copolymer PP resin engineered for durability and structural integrity. Combining high stiffness and excellent impact strength, it’s ideal for automotive components, industrial furniture, and appliance housings. This tairipro pp resin delivers reliability in demanding environments while streamlining production efficiency.

- Character: High stiffness,Good impact strength

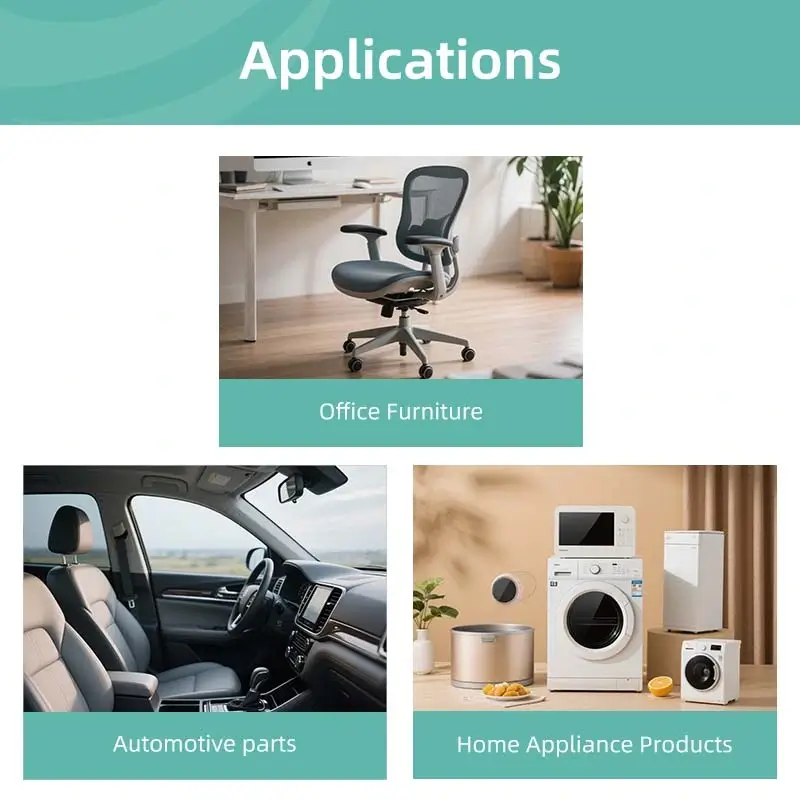

- Application: Automotive parts, Furniture,Appliances

Key technical data (ISO)

- Melt Flow Index: 9 g/10 min (230°C)

- Heat Deflection Temp: 120°C

- Molding Shrinkage: 1.4–1.8%

- Specific Gravity: 0.9

- Processing: 180–230°C screw temp; 30–60 kg/cm² pressure

Application

- Automotive Parts: Bumpers, interior panels, and battery casings that endure impacts and heat.

- Furniture: Durable storage bins, pallets, and outdoor chairs requiring structural rigidity.

- Appliances: Washing machine components, vacuum housings, and power tool bodies needing flame resistance.

Related TAIRIPRO® PP Plastics

FCFC TAIRIPRO® T2502 PP Resin

FCFC TAIRIPRO® T1202 PP Resin

FCFC TAIRIPRO® T1002 PP Resin

FCFC TAIRIPRO® S1803 PP Resin

FCFC TAIRIPRO® S1005 PP Resin

FCFC TAIRIPRO® S1003 PP Resin

FCFC TAIRIPRO® S1040 PP Resin

FCFC TAIRIPRO® S1019 PP Resin

FCFC TAIRIPRO® K2051 PP Resin

FCFC TAIRIPRO® K1525 PP Resin

FCFC TAIRIPRO® K1108 PP Resin

FCFC TAIRIPRO® K1080 PP Resin

FCFC TAIRIPRO® K1023 PP Resin

FCFC TAIRIPRO® K1011AG PP Resin

FCFC TAIRIPRO® F2011 PP Resin

FCFC TAIRIPRO® F2003 PP Resin

FCFC TAIRIPRO® F1611 PP Resin

FCFC TAIRIPRO® B1101 PP Resin

FCFC Formosa TAIRIPRO® T4002

FCFC Formosa TAIRIPRO® T3002

FCFC Formosa TAIRIPRO® F4008

FCFC Formosa TAIRIPRO® F4007

FCFC Formosa TAIRIPRO® F4006

FCFC Formosa TAIRIPRO® K4750

FCFC Formosa TAIRIPRO® K4715

FCFC Formosa TAIRIPRO® K4650

FCFC Formosa TAIRIPRO® K4515

FCFC Formosa TAIRIPRO® K4038

FCFC Formosa TAIRIPRO® T8002

FCFC Formosa TAIRIPRO® B8001A3

Advanced Manufacturing